Optotherm, Inc. launches MW640-15 MWIR mamera for high-sensitivity IC failure analysis

Optotherm, Inc. has introduced the MW640-15, a high-sensitivity mid-wave infrared (MWIR) thermal imaging camera engineered for advanced electronics failure analysis, lock-in thermography, and microscopic temperature measurement.

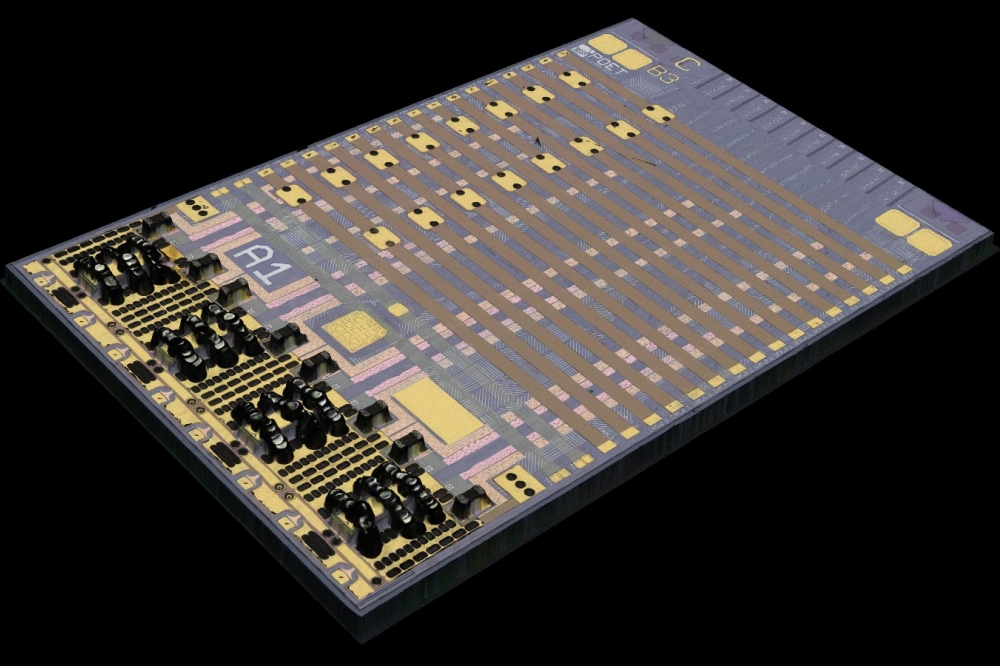

Designed for both front-side and back-side IC inspection, the MW640-15 delivers NETD <20 mK sensitivity, significantly reducing lock-in thermography test times while enabling detection of extremely small thermal variations.

The system’s high spatial resolution allows discrimination of IC features down to 1 μm, supporting detailed analysis of sub-micron device structures.

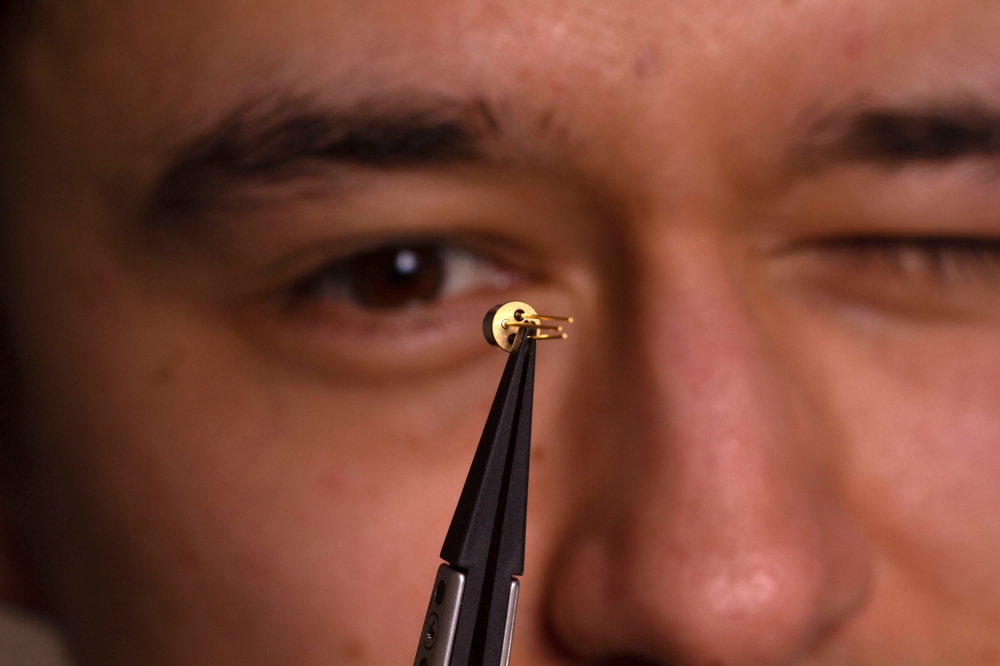

At the core of the camera is a 640 × 512, 15 µm pitch MCT detector cooled to 80 K using a Stirling engine.

The platform operates at frame rates up to 115 Hz in full-frame mode and 1,550 Hz in windowed mode, enabling dynamic thermal analysis of active semiconductor devices.

The MW640-15 supports applications including hot spot detection below 0.0001 °C, junction temperature measurement, and transient thermal characterisation.

These capabilities are particularly valuable for engineers working on high-performance logic, power devices, compound semiconductors, and advanced photonic integrated circuits (PICs), where localised heating can directly impact performance and reliability.

The camera can operate as a standalone instrument or be integrated into Optotherm’s Sentris turnkey thermography systems.

“We developed the MW640-15 for failure analysis engineers who require high spatial resolution and measurement sensitivity, and the ability to perform IC backside analysis,” said Rich Barton, President and Technical Director at Optotherm.

With increasing device complexity and power density in advanced semiconductor and photonic platforms, high-precision thermal imaging continues to play a critical role in accelerating root-cause analysis and improving device reliability.