GlobalFoundries to open Advanced Packaging and Photonics Center in New York

The new centre aims to enable advanced packaging, assembly and testing for GF’s silicon photonics platform, and the secure manufacturing and processing of chips used in sensitive national security systems, so that they never leave the US during production

GlobalFoundries has announced plans to create a new centre for advanced packaging and testing of US-made essential chips within its New York manufacturing facility. Supported by investments from the State of New York and the US Department of Commerce, the centre, which GF says is the first of its kind, aims to enable semiconductors to be securely manufactured, processed, packaged and tested entirely onshore in the US to meet the growing demand for GF’s silicon photonics and other essential chips needed for critical end markets including AI, automotive, aerospace and defence, and communications.

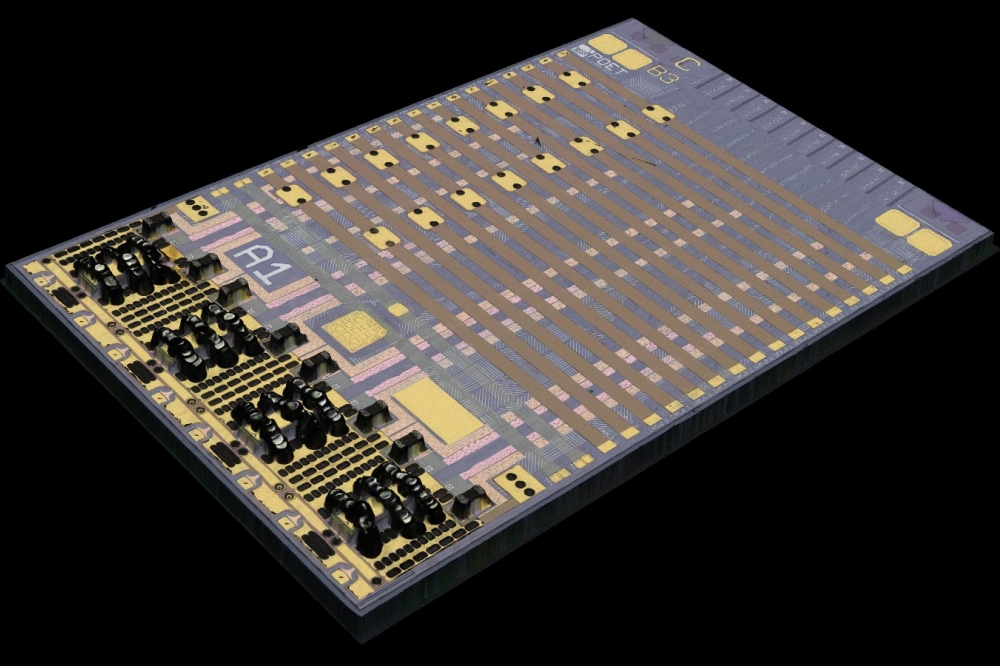

Growth in AI is driving the adoption of silicon photonics and 3D and heterogeneously integrated (HI) chips to meet power, bandwidth and density requirements in datacentres and edge devices. Silicon photonics chips are also positioned to address power and performance needs in automotive, communications, radar, and other critical infrastructure applications.

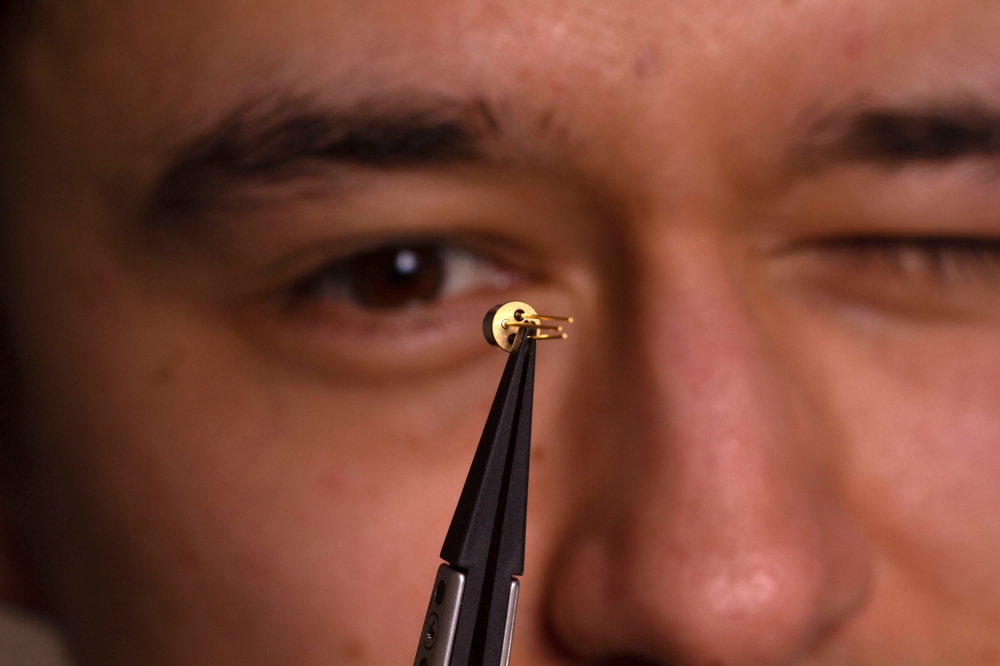

To meet this growing demand, GF’s New York Advanced Packaging and Photonics Center is expected to offer advanced packaging, assembly and testing for GF’s differentiated silicon photonics platform, which brings together optical and electrical components on a single chip to realise power efficiencies and performance advantages.

The centre also plans to offer full turnkey advanced packaging, bump, assembly and testing for aerospace and defence customers under GF’s Trusted Foundry accreditation, allowing chips used in sensitive national security systems to never leave the US during production.

New production capabilities for the advanced packaging, wafer-to-wafer bonding, assembly and testing of 3D and HI chips using GF’s 12LP+, 22FDX, and other leading platforms, will also be provided by the centre, GF adds.

“We’re proud to partner at the state and federal level on this new centre, which is a direct response to our customers asking for more geodiversity in their supply chains and additional support with advanced packaging solutions for GF silicon photonics, Trusted, and 3D/HI offerings,” said Thomas Caulfield, president and CEO of GF. “The New York Advanced Packaging and Photonics Center will be unique in our industry and will play a vital role in the continued growth of the Empire State’s world-class semiconductor manufacturing and innovation ecosystem.”

The New York Advanced Packaging and Photonics Center aims to expand GF’s advanced packaging capabilities – the process of transforming chips into individual packages ready for end-product use – to provide customers an end-to-end US-based solution for chips made at GF’s New York manufacturing facility. Across the semiconductor industry, most advanced packaging today takes place in Asia.

GF says its overall investment in the New York Advanced Packaging and Photonics Center is expected to be $575 million, with an additional $186 million investment in research and development over the next 10-plus years. These efforts are expected to create approximately 100 new full-time GF jobs in New York over the next five years.

New York state will provide up to $20 million in new support for the new centre, which is in addition to the previously announced $550 million in support for GF from the New York State Green CHIPS programme. The US Department of Commerce will provide up to $75 million in direct funding to support the centre, supplementing the previously announced GF award under the CHIPS and Science Act.

GF employs approximately 2,500 people at its Malta, New York, fab and has invested more than $16 billion in the facility since it opened in 2011. GF’s New York fab has Trusted Foundry accreditation and manufactures secure chips in partnership with the US government.