OpenLight achieves Telcordia GR-468 qualification for silicon photonics components

The company says the completion of this process, which involves 2,000 hours of long-term reliability testing, will give customers greater confidence in its heterogeneously integrated silicon photonics solution

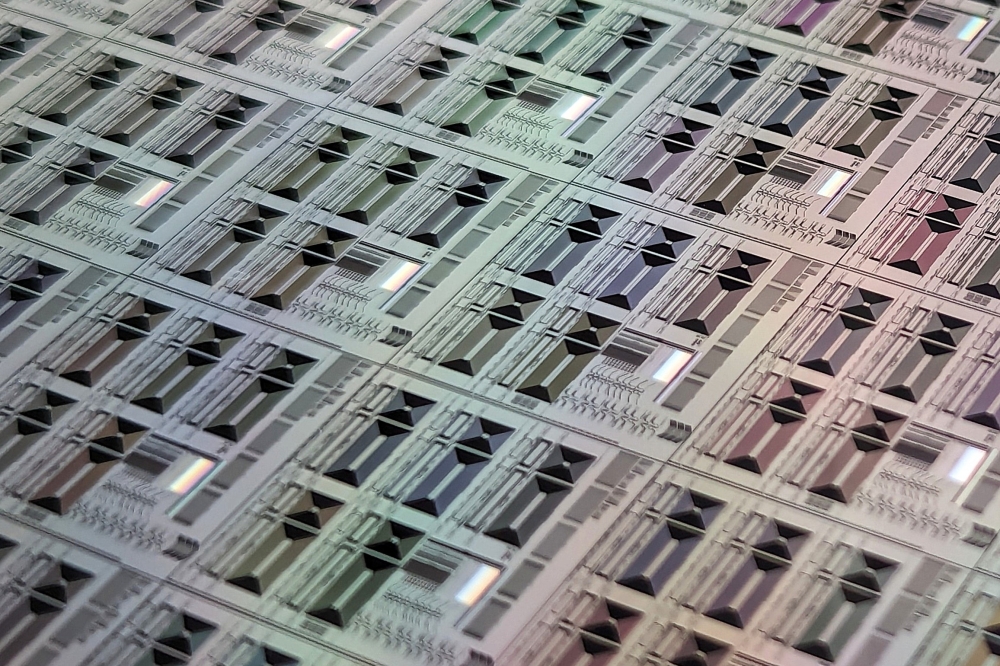

OpenLight, a company focusing on custom PASIC chip design and manufacturing, has announced the successful completion of Telcordia GR-468 qualification for all active components in its Photonic Design Kit (PDK) based on Tower Semiconductor's PH18DA process. The company says this achievement validates that its solution meets the necessary industry reliability standards, a key requirement for the widespread deployment of photonics technologies, and provides significant assurance in the design and manufacturing process of advanced optoelectronic components for applications in the growing silicon photonics industry.

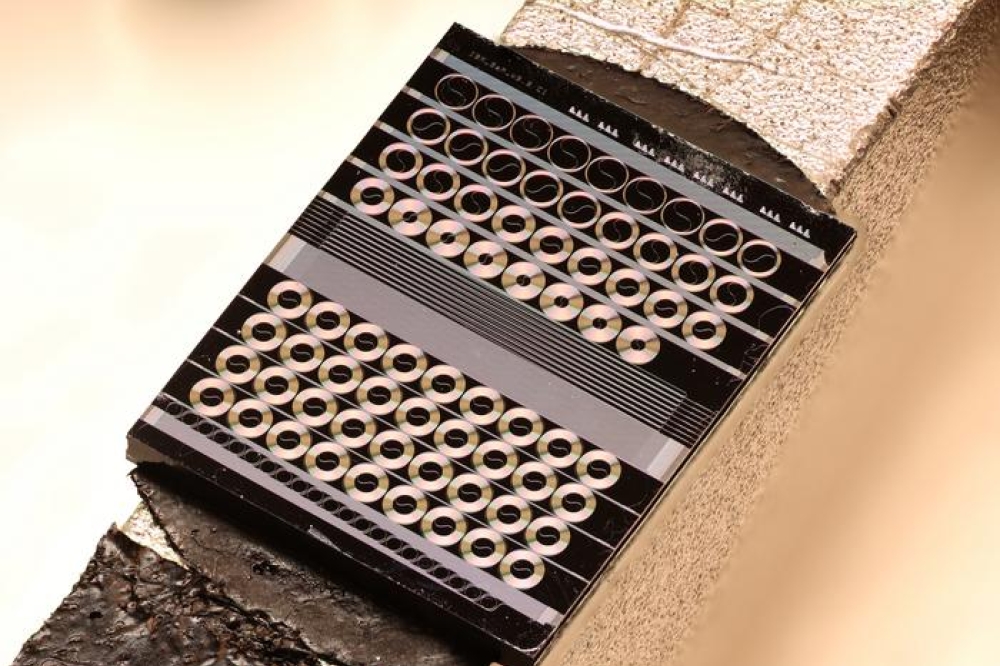

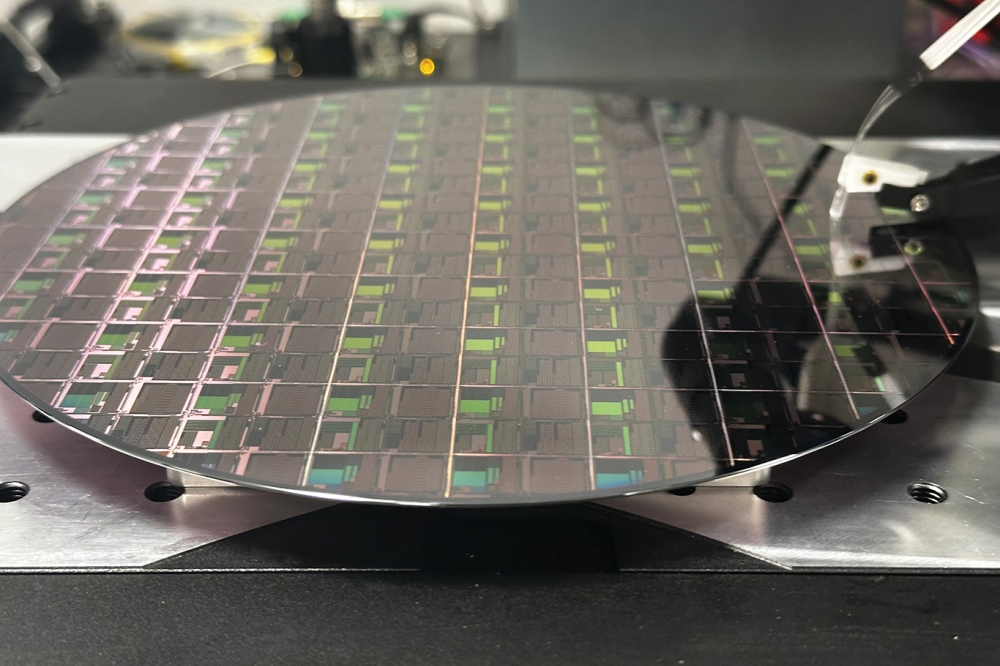

The GR-468 qualification process requires components to undergo 2,000 hours of long-term reliability testing, including high-temperature operating life, damp heat storage, temperature cycling, temperature and humidity bias, and electrostatic discharge-human body model testing. During the testing, two lots exceeded 5,000 hours with zero failures, while another exceeded 15,000 hours without any failures, demonstrating their exceptional reliability. This milestone includes the qualification of lasers, electro-absorption modulators and photodiodes, which are based on indium phosphide (InP) and integrated into silicon wafers.

For the deployment of any photonic technology, customers require component building blocks to meet the industry's standard reliability requirements. According to OpenLight, achieving the GR-468 qualification provides significant assurance in the design and manufacturing process of advanced optoelectronic components, which are critical for applications in the growing silicon photonics industry. With this qualification, the company says it is now ready for the highly scalable productization of these components and their deployment in next-generation photonics applications.

Beyond passing the GR-468 qualification, OpenLight says its solution offers two major advantages that set it apart in the silicon photonics market: lasers that are heterogeneously integrated into silicon without the need for a laser facet, eliminating the risk of catastrophic optical mirror damage; and the use of a single epitaxial (EPI) growth process with no re-growth, grating or blocking junctions, ensuring high material integrity and exceptional reliability, with over 99 percent of InP EPI transferred to the silicon wafer without defects.

“The breakthrough in long-term reliability of OpenLight's optoelectronic components is a significant step in the evolution of silicon photonics,” said Adam Carter, CEO of OpenLight. “While the industry is already comfortable with externally coupled lasers in silicon photonics, the next frontier lies in heterogeneously integrated silicon photonics. The successful GR-468 qualification and long-term reliability data will give our customers the confidence needed to transition to this next level of integration, opening the door for the widespread adoption of our high-performance components in silicon photonics, and we're excited to see the industry embrace this next generation of technology.”