FIC Global expands optical transceiver business

The company has tripled optical module production capacity over the past two years to meet the rapidly evolving demands of silicon photonics, and plans to announce new manufacturing facilities later this year

FIC Global Inc., a company focusing on packaging and installing semiconductors on optical modules, has announced a significant expansion of its optical transceiver business to meet the rapidly evolving demands of silicon photonics optical transceivers for next-generation datacentre networking.

As AI-powered datacentres scale in complexity and density, co-packaged optics (CPO) switches have emerged as a solution for ultra-fast intercommunication, reduced energy consumption, and minimal latency, with the new benchmark for data transmission speeds now 1.6T. Optical transceivers – key components that convert electrical signals into light data for transmission over fibre optic cables – are driving this transformation.

“Our expansion reinforces FICG's role at the heart of the optical transceiver revolution,” commented Leo Chien, chairman of FICG. “Powered by FICG's cutting-edge manufacturing technology, competitive yields, and comprehensive capabilities, we are innovating at the speed of light to enable 1.6T and 3.2T.”

As part of the expansion, the company plans to announce new manufacturing facilities later this year.

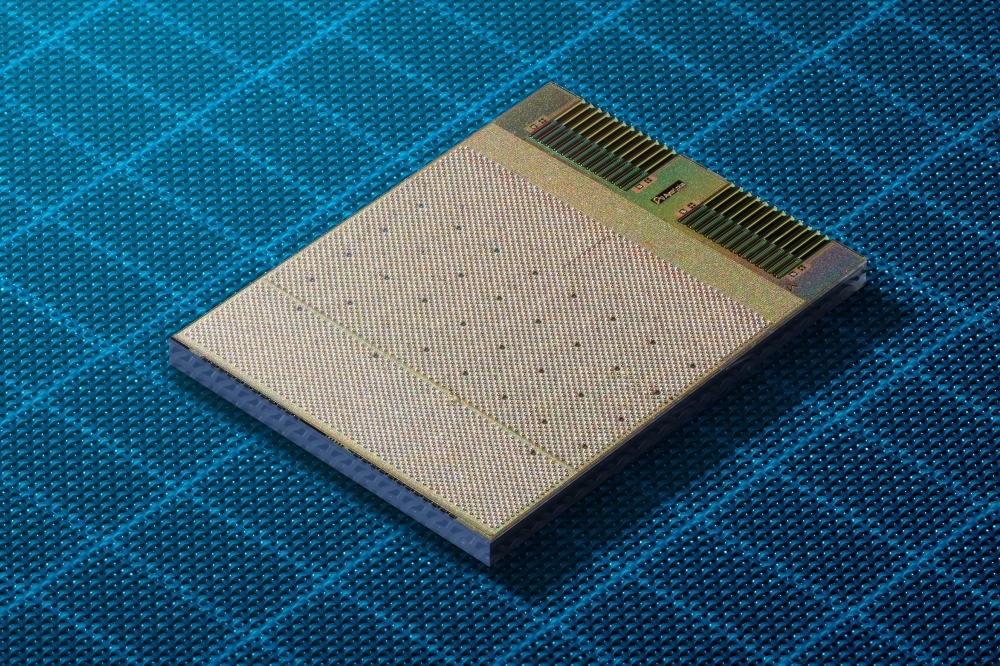

FICG says its leadership is built on a legacy of expertise in joint design manufacturing (JDM) for optical modules. Working closely with semiconductor makers upstream and optical transceiver customers downstream, the company aims to leverage advanced techniques to package electronic and optical semiconductors and install them onto the core printed circuit boards of optical modules.

With experience in optical transceivers since 2008, these now represent over 50 percent of FICG's revenue. The company highlights that it supplies major players worldwide, collaborates closely with chip manufacturers in Taiwan, and has tripled optical module production capacity over the past two years. FICG also says it is actively innovating to prepare for transmission speeds to double from 1.6T to 3.2T.

The company adds that it particularly stands out for its ability to integrate higher-tech manufacturing processes like 2.5D and 3D semiconductor packaging and bare-die flip chip installation with the more mainstream surface mount technology for the rest of a PCBA, enabling customers to consolidate and simplify their supply chains.