Aeva introduces first FMCW-based laser displacement sensors

The company, which is known for its Atlas automotive LiDAR, says its new Eve 1D product, which also leverages silicon photonics, delivers sub-micron repeatability for high-volume manufacturing automation applications

Aeva, a company developing next-generation sensing and perception systems based on silicon photonics, has announced the Aeva Eve 1 line of high-precision sensors, starting with Eve 1D, which the company describes as the industry’s first FMCW-based laser displacement sensor designed for high-volume and inline industrial automation applications, including factory and process automation. The new product aims to address the growing $4 billion global laser displacement sensor market.

Laser displacement sensors are redefining precision measurement in modern production environments. They measure the distance between the sensor and a target surface without physical contact, using a laser beam. Designed for high-speed, non-contact operation, the sensors are designed to measure accuracy down to the micrometre level, which is about one hundredth of the thickness of a human hair. Commonly used in industrial automation, quality control, and precision manufacturing, manufacturers can use these sensors to measure the thickness, height, or position of components, monitor the velocity or vibration of moving parts, and check for flatness or warping in manufacturing.

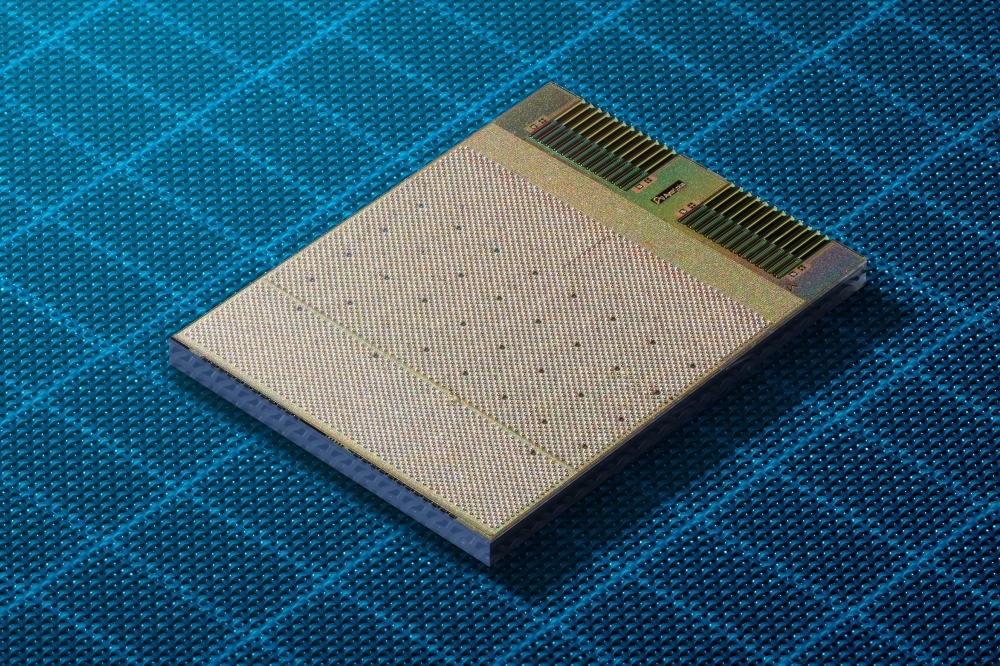

According to Aeva, the new Eve 1D laser displacement sensors are the industry’s first to leverage frequency-modulated continuous-wave (FMCW) laser technology and are powered by Aeva’s CoreVision lidar-on-chip modules. The company says they leverage the same silicon technology built from the ground up to meet the strict reliability and durability requirements of automotive applications, fine-tuned for high-precision sensing.

Each module is built using silicon photonics to integrate key sensor elements on silicon. Combined with Aeva’s proprietary precision sensing software, Eve 1D provides a scalable, software-defined product free from the limitations of industry-standard laser triangulation technology in performance, cost, and form-factor, the company adds.

“Built on the same core FMCW technology found in our Atlas automotive 4D LiDAR products, our Eve 1 line of sensors opens an entirely new market with significant revenue opportunity for Aeva,” said Mina Rezk, co-founder and CTO at Aeva. “Eve 1D delivers a unique combination of performance, cost, and scalability, and addresses many of the drawbacks of today’s laser displacement sensor technologies. The sensors will help increase quality control and precision as the global manufacturing industry becomes increasingly automated and reliant upon advanced sensor technologies.”

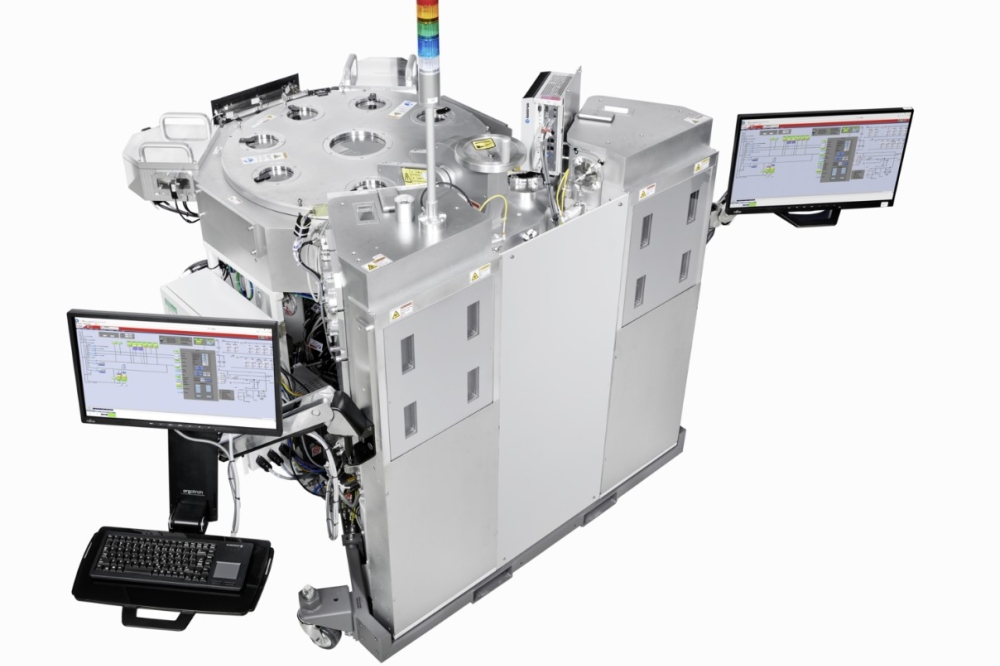

According to Aeva, the Eve 1D sensors are designed to measure down to sub-micron precision and can operate across a wide range of target standoff distances from 100 millimetres up to 20 metres, all within the same compact all-in-one form factor that combines measurement and data processing. The company says they outperform state-of-the-art displacement sensors with an accuracy of 100 parts per million (0.01 percent linearity) and operate at high measurement speeds. These advantages could allow for faster, precise inspection, giving customers high levels of throughput, improved quality control, and cost efficiency in their manufacturing processes.

By combining all optical components and data processing into a compact, single box design, Eve 1D aims to allow for a seamless plug-and-play experience. Compared with industry-leading displacement sensors that use traditional triangulation or time-of-flight based measurement methods, Aeva says the Eve 1D provides important advantages, including reliable precision across various materials and surface types and suitability for any lighting environment, since it is unaffected by ambient light.

The company adds that the new sensor also has a unique coaxial laser beam design, enabling versatile scanning in small clearance areas without occlusions or sensitivity to scan direction, and can accurately capture radial velocity, expanding functionality to include vibrometry and velocimetry to precisely measure the vibration of rotating parts like fans and detect the speed of moving parts like conveyor belts.