Xanadu and Applied Materials partner on photonic quantum computing

The companies are collaborating to develop the first 300 mm high-volume fabrication processes for a key component of photonic quantum computers, and aim to complete a basic demonstration of their platform’s capabilities towards the end of this year

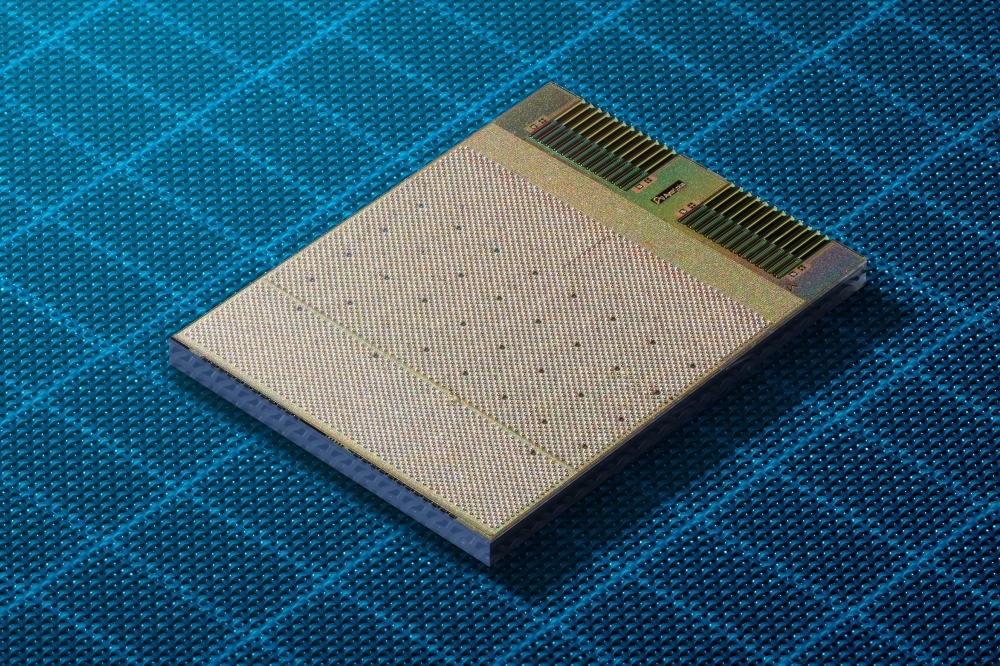

Xanadu, a photonic quantum computing company based in Toronto, Canada, has announced it is collaborating with Applied Materials, Inc., a materials engineering company, to develop the first 300 mm high-volume-compatible process for building superconducting transition edge sensors (TESs). These TESs are a core component of photon-number-resolving detectors (PNRs), which are key elements that enable the qubit state preparation process in Xanadu’s photonic quantum computers.

According to Xanadu, the demonstration of its Aurora quantum computer, published in Nature earlier this year, paved the way towards a utility-scale photonic quantum computer by demonstrating the first-ever modular, scalable, and networkable quantum computer. As the company shifts its focus towards reducing optical loss throughout different components to achieve fault tolerance, it is also looking ahead to when its quantum computer will be ready to be scaled up to a fully-fledged quantum datacentre. Such scaling will require mass semiconductor manufacturing capabilities of various components, including TESs for PNRs, to reduce production costs and meet the stringent demands on detector performance, quality, and production volume required.

“Utility-scale quantum computers have exacting fabrication processing demands that require us to continually push what is possible in the fab,” said Elliott Ortmann, head of fabrication process engineering at Xanadu. “Applied Materials has been a tremendous collaborator for us over the years and we are excited to continue working with them on new materials fabrication challenges. Developing the first 300 mm process for TESs opens up the ability to leverage the most advanced fabrication tools to produce higher-quality and better-performing devices.”

Robert Visser, vice president of engineering in the office of the CTO at Applied Materials, commented: “Applied Materials’ collaboration with Xanadu is focused on developing scalable fabrication approaches that can create better quantum devices for the industry. Xanadu’s TES design requires advanced materials engineering and process control – areas where Applied brings decades of expertise with 300 mm semiconductor platforms.”

This collaboration builds on previous work done jointly between Xanadu and Applied Materials which focused on materials optimisation of TES fabrication processes. Over the next year, the two teams aim to demonstrate the first 300 mm platform for building TESs for PNRs. The teams are planning to complete a basic demonstration of the platform’s capabilities towards the end of 2025, after which they intend to continue optimising its performance to meet the demands of high-throughput and high-reliability fabrication before ramping up for mass manufacturing.