Technical Insight

InP/InGaAsP PIC fabrication process is muti-faceted

Scientists at the Eindhoven University of Technology based in the Netherlands have developed a new process which combines all the process steps needed in creating a Photonic Integrated Circuit (PIC)

Researchers including Boudewijn Docter, from the Opto-Electronic Group have developed a ‘generic integration technology’ in which all functionalities required in a Photonic Integrated Circuits (PIC) can be realized.

InP-based materials are historically the material of choice for laser devices used in fiber optic communication systems. It is therefore the most interesting material to use for complex PICs. However, the fabrication process required to create these circuits is much more complex than that needed to manufacturesingle laser devices.

Figure 1: Schematic cross-section of the different waveguide types

The fabrication process must be capable of producing high-performance amplifiers and lasers, but also needs to facilitate a large variety of passive waveguide circuits (filters, splitters, phase modulators, etc.)

The generic integration technology developed by the researchers allows the designer to build basic active and passive components using both shallowly etched waveguides (for low loss interconnects and efficient amplifiers) and deeply etched waveguides (for smaller bend radii and efficient phase shifter sections). A cross-section of the different waveguide types is shown in Figure 1.

The upgraded fabrication process makes it possible to etch narrow slots into the deeply etched waveguides. This allows the realization of deeply etched broadband mirrors in the passive and active waveguides.

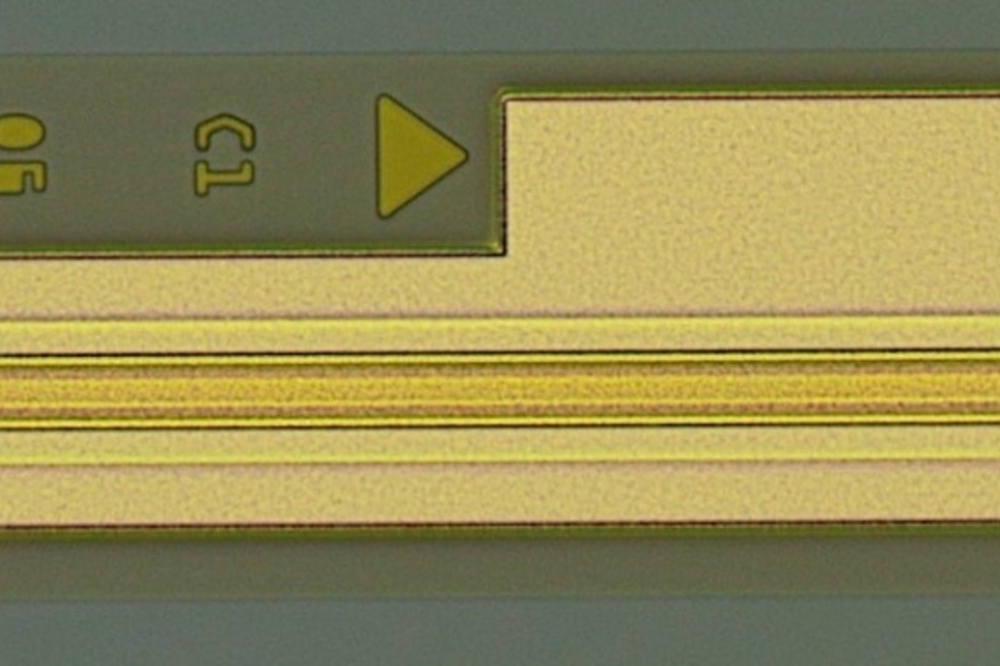

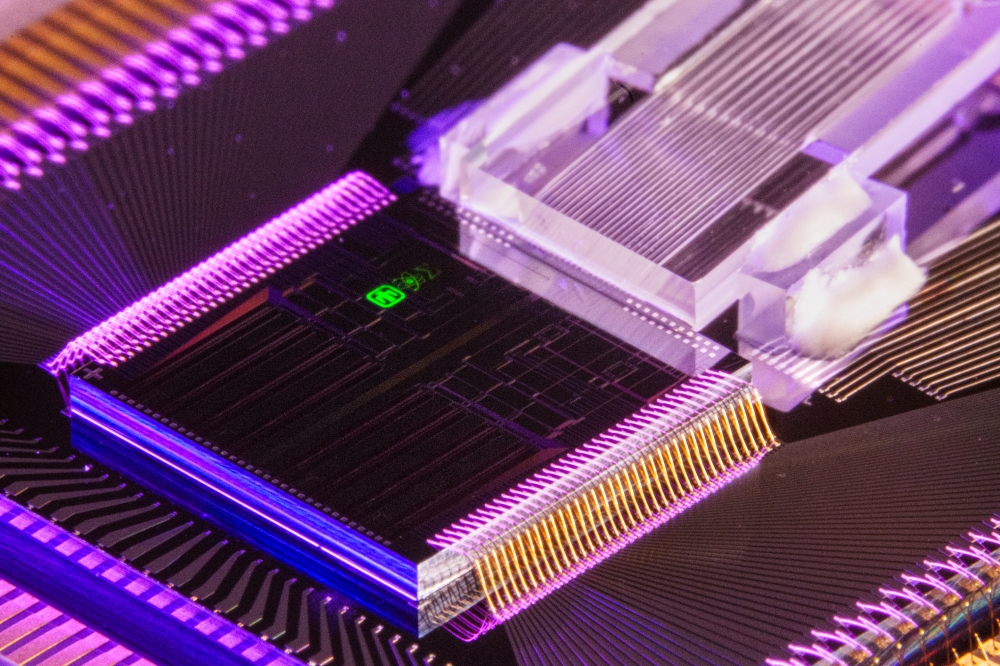

Figure 2:Side-view of a deeply etched broadband mirror. After etching the gaps are filled by a polymer

A schematic side-view of such a mirror is shown in Figure 2 and the resulting reflection/ transmission spectra are plotted in figure 3. For the mirrors it is very important that the dimensions of the gaps are accurately defined, since the reflection from all interfaces must be in phase with each other. In this specific design there is approximately ¾ of the wavelength (λ = 1.55 μm in vacuum) between each interface. Also the etch depth and the profile inside the narrow slots is very important. A small deviation in sidewall angle can reduce the reflectivity significantly.

These structures were fabricated using an Oxford Instruments Plasmalab System100 ICP. The deeply etched structures are etched using a Cl2: Ar:H2 chemistry. This process provides a straight and smooth etching profile, also in the narrow mirror slots. However, the etch rate is quite high (~2 μm/min) and is therefore not so suitable for the shallowly etched structures, since the etch depth should be accurately controlled. Hence a more gentle process using cycles of CH4:H2 plasma alternated with an O2 descum step was used.

Figure 3:Calculated reflectivity (solid) and transmission (dashed) spectra of a 3-period deeply-etched DBR mirror

Figure 4: SEM images of shallow-etched waveguide (left), deeply-etched waveguides (middle) and deeply-etched mirror (right).mirror.

The results of the different processing steps are shown in the SEM images in figure 4. The broadband mirrors can be used in a large variety of devices. One of the first applications that was realized to demonstrate the capabilities of the new fabrication process is a novel ultra-fast tunable laser.

This new device can switch between a set of discrete wavelengths within just a few nano-seconds – 100 times faster than today’s commercially available tunable lasers – which makes it very interesting in a variety of optical telecommunication and fiber sensing applications.

Further details of the research are available on the Oxford Instruments website.