Technical Insight

New players make a big splash at OFC (Optical fibers Communication Conference)

Among the 970+ exhibitors at this year's Optical Fiber Communication conference were a number of companies seeking to revolutionize the fiber-optic components industry. Tim Whitaker and Richard Dixon report from Anaheim, California.

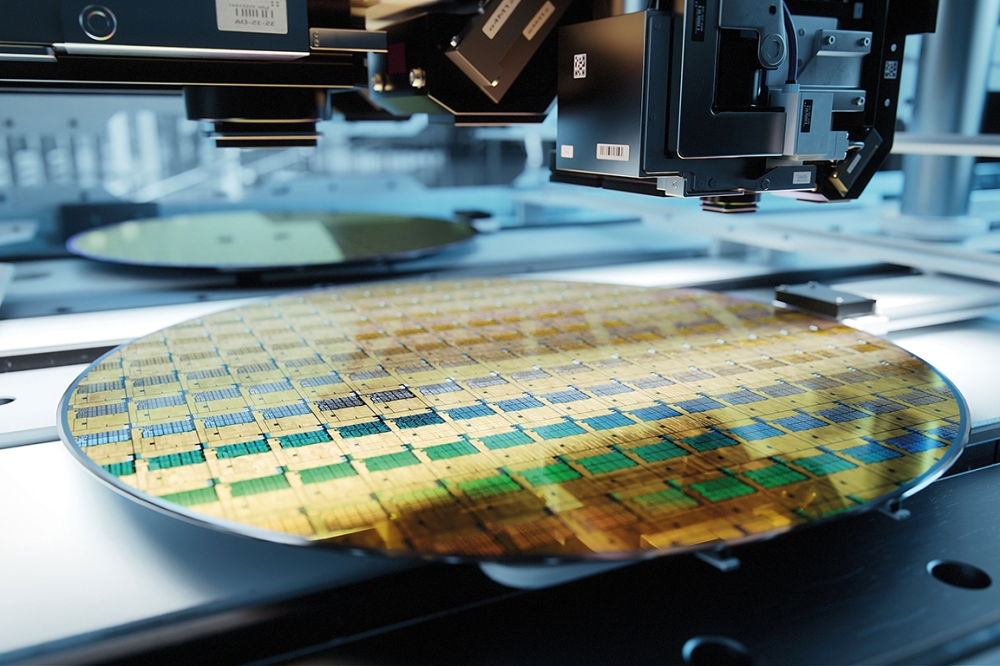

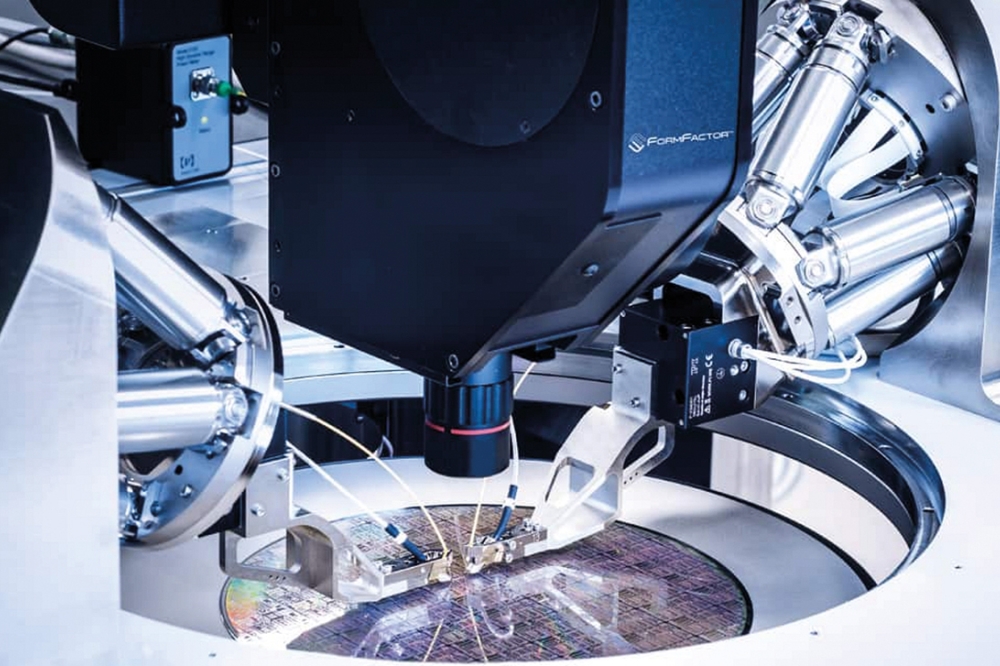

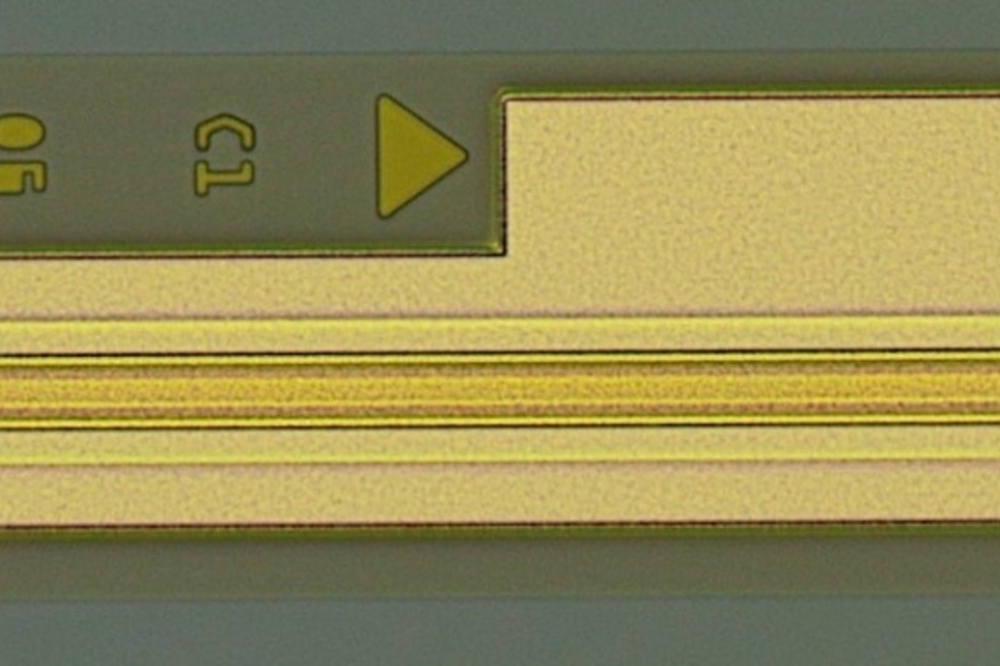

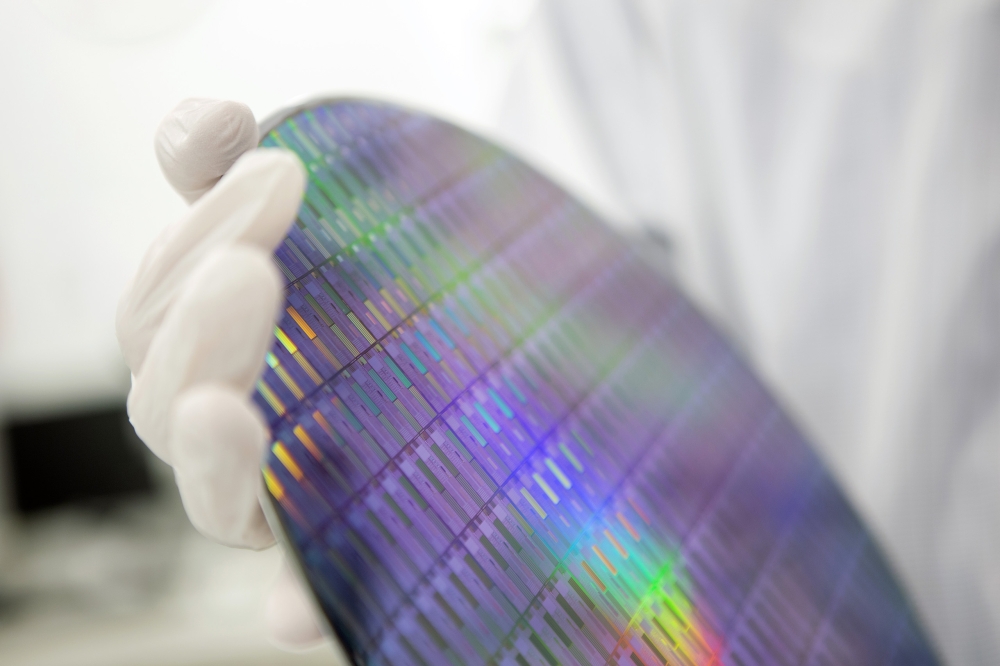

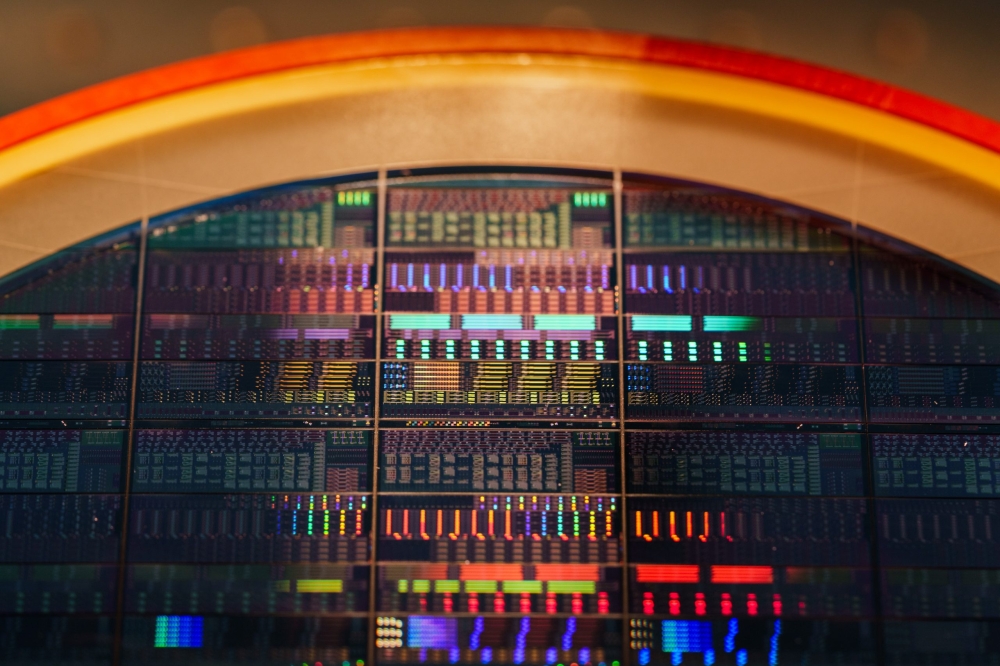

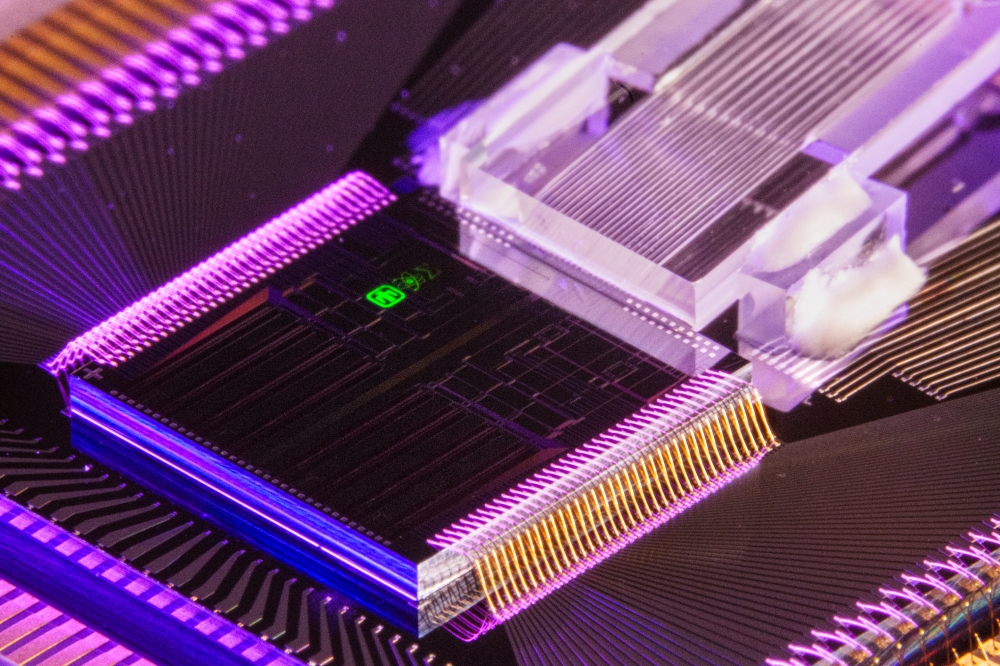

Although their booths were dwarfed by the likes of companies such as Corning and JDS Uniphase, several much smaller optical component vendors were showing demos of some very exciting technologies at this year s Optical Fiber Communication conference (OFC, held 1921 March in Anaheim, CA). Here is our selection of the most interesting, in no particular order. Genoa Among the major components of optical networks, the optical amplifier is the only one that has not been widely adopted in chip form. Instead, the commonly used EDFA is a box containing pump lasers, Er-doped fiber, gain-flattening filters and various other parts. Chip-based amplification is very attractive since it potentially offers smaller size, lower cost and power consumption, and high levels of integration. Also, especially in the metro environment, amplifiers need to offer linear gain and to be able to accommodate any data rate, handle multiple wavelengths without crosstalk, and work in switched networks. Chip-based amplifiers already exist in the form of semiconductor optical amplifiers (SOAs), but these devices suffer from crosstalk when more than one wavelength channel is amplified. A solution introduced at OFC by Genoa, a company based in Fremont, CA, is the single-chip linear optical amplifier (LOA). This InP-based device can simultaneously amplify all wavelengths across the C-band (35 nm bandwidth) with 13 dB gain. shows a size comparison of an EDFA and the LOA in a 14-pin butterfly package. The LOA has a deceptively simple structure; essentially it is a monolithic, 1550 nm InP-based VCSEL. Of course, this type of device is still very much a commercial rarity. The active region of the VCSEL acts as a waveguide for the signal as it passes through the device. The VCSEL pumps an excess of photons into the gain medium, amplifying all wavelengths at the same time. "We can observe the light coming out of the LOA," says Jim Witham, Genoa s vice-president of sales and marketing. "When the power of the input optical signal is increased, the light output dims as more photons are used for amplification." Genoa operates a 45 000 sq. ft InP wafer fab in Fremont, CA which contains two MOCVD machines as well as capabilities for wafer fabrication, packaging and testing. A second facility is being built in Eindhoven, the Netherlands, that will eventually also have InP fab capabilities. The company has recently completed a $75 million funding round. "We re concentrating on the C-band LOA at the moment," explains Witham. "Initial customer testing is under way, and we will offer commercial samples by fall of this year." By slightly changing the structure and materials of the device, the LOA can be made to work anywhere in the transmission band in the fiber. "As well as looking at other bands, we will also build amplet arrays, in addition to increasing the available output power," says Witham. "Looking further ahead, we will be introducing higher levels of integration on InP, building lossless switches and then moving into multifunctional optoelectronic ICs." Princeton Lightwave To use the company s own words, Princeton Lightwave Inc. (PLI) "emerged from stealth mode" shortly before OFC and announced its plans to deliver a clutch of advanced optoelectronic components. These include high-power 1480 and 14xx nm pump modules and sub-assemblies, broadband gain chips and high-power DFB source lasers. PLI is privately held, and backed by $28.5 million in venture funding. The company was spun out from Sarnoff, and has an exclusive license to a broad patent portfolio. PLI carries out vertically integrated manufacturing of InP-based devices, from epitaxy to packaging, in its 90 000 sq. ft facility in Cranbury, NJ. PLI s broadband gain chip (BCG see ) is an InP chip-on-carrier that is used as the gain element within an external-cavity laser (ECL). Tunable ECLs have recently been announced by several companies, namely New Focus, Blue Sky Research and Iolon. The new BCG allows customers to build ECLs with output powers of 40 mW while enabling tuning over an entire (S, C or L) band. PLI has also developed high-power 14xx nm pump lasers for Raman amplifiers and 1480 nm devices for pumping EDFAs. Output powers have hit 500 mW in modules, while PLI announced in April that it has demonstrated 1 W of output power from 1480 and 14xx nm chips. Novalux After a long wait Novalux finally revealed details of its surface-emitting laser, and announced two 980 nm products. The first, a singlemode module for pumping EDFAs, is available with output powers of 200 mW and 360 mW, while the second is a multimode pump in the 750 mW power range for the emerging dual-clad fiber market. Novalux planned to begin sampling these devices in April. Novalux says that the EDFA pump-laser market is driving its current business strategy. "The NECSEL is really a very flexible platform," explains chief technology officer Aram Mooradian. "This is the first of what will be a long line of affordable, high-performance and highly scalable NECSEL laser products for a wide range of telecom applications." The NECSEL (for "Novalux extended-cavity surface-emitting laser") employs a three-mirror, coupled-cavity design (see ). Two of these mirrors are epitaxial DBR layers surrounding the InGaAs/GaAsP gain region. The third mirror is external to the device, forming an extended cavity. The epitaxial structure is grown by MOCVD on 4 inch GaAs wafers, and contains several 8 nm wide, strain-compensated InGaAs quantum wells within the active region. The device is mounted p-side down onto a heat sink, and emission occurs through the substrate. Current is injected through a circular aperture defined by a silicon nitride layer. The n-contact has a larger circular aperture with an anti-reflection coating to allow the beam through to the external mirror. The large aperture serves to keep the optical intensity well below the catastrophic damage level, and also results in a circular beam with low divergence. The extended passive cavity controls both the longitudinal and transverse modes of operation. CW output power levels of 500 mW have been demonstrated in a TEM00 mode with a single frequency stabilized by the short-cavity FabryPerot. The circular output beam results in coupling efficiencies of 90%, with 420 mW CW of coupled power demonstrated from 150 m diameter lasers and uncoated singlemode fibers. In multimode devices more than 1 W of output power has been demonstrated, along with coupling efficiency of greater than 85%. The devices have the advantage of maintaining fundamental mode operation even as device diameter increases, allowing scaling to still higher power levels. Reliability is a key concern for manufacturers of pump lasers for EDFAs. Preliminary accelerated lifetime tests with more than 2000 hours of operation show that NECSELs exhibit reliability characteristics similar to those of low-power VCSELs. Novalux says that this is not surprising given the similarity in materials, current densities and operating temperatures. As a surface-emitting laser technology the NECSEL has other features in common with regular VCSELs, not least the ability to test devices on the wafer prior to dicing and packaging. Novalux is focusing on wafer-scale manufacturing processes, and sees the use of 4 inch GaAs wafers as a major advantage for high-volume production. Based in Sunnyvale, CA, the firm has a 16 000 sq. ft building with class-10 cleanroom space for wafer processing, together with a second 22 000 sq. ft building for packaging and assembly. Last fall Novalux leased a 100 000 sq. ft facility that will house its highly automated packaging processes. Princeton Optronics The name is new, but Princeton Optronics has been around since 1993, and last year generated several million dollars in revenues from its RF-microwave products. The company began life as another spin-off from Sarnoff, and changed its name from Princeton Electronic Systems in 2000 to reflect its contributions to the optical components market. Princeton Optronics is developing several interesting products, one of which is a tunable laser combining a high-power VCSEL with MEMS and an integrated wavelength locker. The company claims that its PowerSweep device delivers 20 mW of power over a broad tuning range of 40 nm, while at the same time providing stability of 1 GHz. Princeton Optronics specifications significantly exceed the performance levels of most of today s commercially available tunable lasers. Sample products (with as-yet-unspecified performance characteristics) will be available this June. The high-power VCSEL technology behind the company s tunable laser will later be applied to solving other high-power requirements within the optical network. In the meantime the firm continues to scale production of its 10.7 Gbit/s modulator driver and 12.5 Gbit/s receiver products. MetroPhotonics Huge efforts are being focused on the need to reduce the cost of components in fiber-optic networks, and planar monolithic integration is one route being followed by a number of companies. MetroPhotonics, a year-old company based in Ottawa, Canada, is focusing on developing photonic ICs using planar waveguides fabricated in silica-on-silicon and InP. Initial products are being built around multiplexer and demultiplexer components, which use echelle gratings rather than the more common arrayed-waveguide (AWG) technology. Echelle gratings and AWG demultiplexers separate wavelengths by introducing phase shifts that result in light of different wavelengths being focused on different spatial locations on an output arc. An AWG achieves this with a fan of waveguides, each of a different length. But in an echelle grating, a vertically etched mirror with a large number of facets has the same function. Light travels through the input waveguide and expands from the end of the guide until it reaches the grating, where it is reflected back to a series of output waveguides, each of which collects a single wavelength. Echelle grating technology has been around for a long time, but MetroPhotonics has only recently established the necessary advanced fabrication techniques, in particular the ability to perform smooth, deep, vertical etches all the way through the waveguide material. Echelle gratings are typically four or five times smaller than AWGs and more easily scaled, since more wavelengths can be added by increasing the number of facets in the echelle grating rather than by adding more waveguides to the array. Like other companies such as Intense Photonics, MetroPhotonics ultimate goal is to use InP to integrate active optoelectronic components such as lasers, modulators and detectors with passive multiplexers and demultiplexers. Teem Photonics Targeting metro applications, Teem Photonics introduced at OFC an ultra-compact erbium-doped waveguide amplifier (EDWA). This gain block is essentially the same as an EDFA, except that amplification takes place inside a waveguide fabricated on glass, rather than within a 20 m spool of specialty fiber. The waveguide is only a few millimeters in length, so the EDWA package which also contains a pump laser, pump multiplexer, pump kill filter and tap coupler measures only 130 27 13 mm, significantly less than a standard EDFA. The waveguide amplifier offers 10 dB gain over the entire C-band, which is much lower than the gain from an EDFA. However, Teem believes that eliminating the Er-doped fiber from its amplifiers makes assembly more straightforward, and results in significant savings in time and labor costs. Axon Photonics Unusually for a small company, Axon Photonics has both passive and active technology platforms; it is manufacturing silica-on-silicon planar lightwave circuits including such components as arrayed waveguides (AWGs), as well as InP-based semiconductor optical amplifiers (SOAs see ). At present the company designs and packages the SOAs; it is in the process of installing chip-fabrication capabilities and will take delivery of an MOCVD system later this year. Axon operates a 25 000 sq. ft facility in Fremont, CA, and a 120 000 sq. ft building in Livermore, CA. The company s SOAs operate at 1310 or 1550 nm and have a strain-compensated structure resulting in low polarization dependence. The modules feature high-gain (15 dB) and a wide 3 dB passband from 1280 to 1610 nm, as well as switch times of less than 1 ns. Axon is also developing hybrid optical subsystems combining active and passive devices. The simplest configuration combines an AWG with an SOA as a pre- or post-amplifier, resulting in a near-lossless AWG module (i.e. the SOA compensates for loss in the AWG). At OFC, Axon showed a simulation of a reconfigurable optical adddrop multiplexer (OADM) consisting of AWGs with hybrid integrated SOAs, which can dynamically add or drop any wavelength from the fiber to the adddrop port. The AWGs ensure low crosstalk and wide passbands; the SOAs act as switches and also ensure a very low insertion loss. Gemfire As WDM systems move to the metro access space, networks will require low cost and flexible amplification. One firm addressing these demands is Gemfire, which recently announced a multi-port 980 nm source array for pumping multiple EDFAs. The compact, board-mountable module has eight independently controlled fiber outputs, providing pump power to eight separate amplifiers. Inside the module is a laser bar with eight emitters, which is integrated with a planar lithium niobate PhotonIC containing tapers, gratings and waveguides. This platform is mounted as a hybrid onto silicon v-grooves for fiber alignment. Based in Palo Alto, CA, Gemfire was formed to develop integrated photonic components for a range of applications, and is now focusing on the telecom market. "We have a great deal of expertise in laser arrays, as well as in planar, wafer-scalable photonic platforms using materials such as glass, polymers and lithium niobate," says Rick Tompane, Gemfire s chief executive officer. Gemfire does not make its own lasers, however. According to Tompane, one challenge is to make the laser bars with a high yield. "We also need to do the coupling, alignment and fiber-attach in an automated, repeatable process across all eight ports." Using hybrid integration onto a planar platform helps; building tapers into the ends of the planar waveguides ensures efficient coupling, and automated assembly is more straightforward as it becomes a 2-D problem on the planar surface. "The new multi-port pump is targeted at low-cost applications like metro," says Tompane, "and high-channel-count systems like cross-connects, where requirements are a little bit of gain together with independent control over every channel, all in the same location." The product can provide 80 mW of kink-free power out of all eight ports; in Gemfire s demo at OFC, 50 mW provided 23 dB gain on a single channel. At the beginning of March Gemfire completed a $63 million round of funding, with participants including Cisco, Corning, Finisar and TriQuint. K2 Optronics The first product to emerge from year-old K2 Optronics is a 2.5 Gbit/s directly modulated, ultra-narrow linewidth ECL. The device contains a FabryPerot laser with an anti-reflection coating on the front facet, which is coupled through a lens to a fiber section containing a Bragg grating. The laser cavity is formed between the grating and the back facet of the FP laser. Compared with directly modulated DFB lasers, these fiber-grating ECLs offer lower chirp and low dispersion over long distances. As the cavity is not entirely within the semiconductor chip, the lasers also exhibit lower temperature-induced variations of properties such as wavelength. Based in Sunnyvale, CA, K2 Optronics recently received $30 million in its second round of financing, but does not intend to install its own laser-chip fabrication facilities.