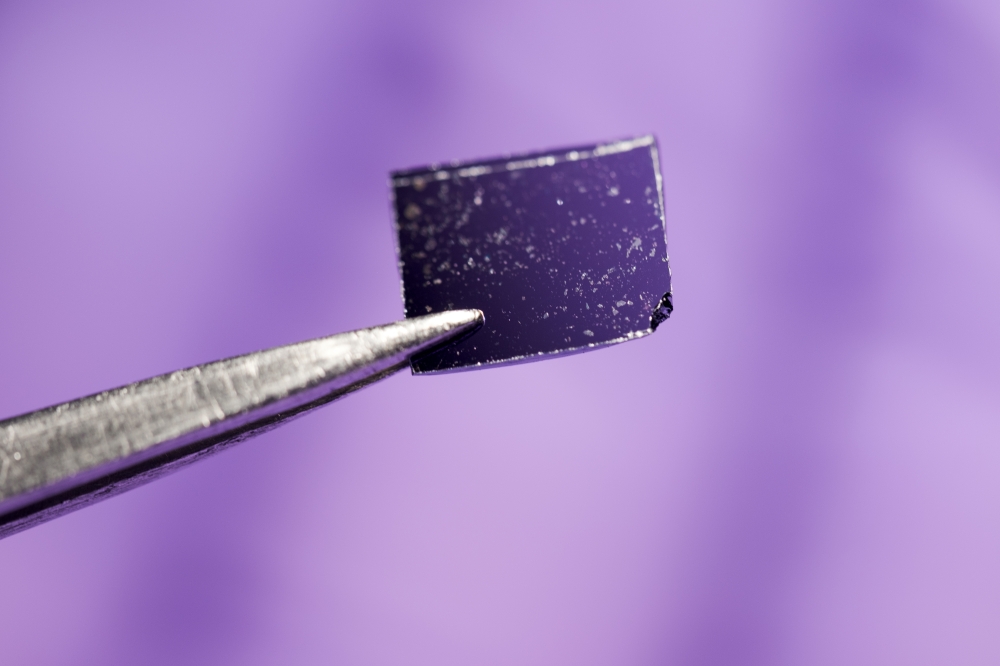

Electronic-photonic quantum chip manufactured in commercial foundry

By designing the system to actively stabilise the silicon microring resonators, researchers say they have made a chip that behaves predictably despite temperature changes and manufacturing variations, marking a milestone for scalable quantum technologies

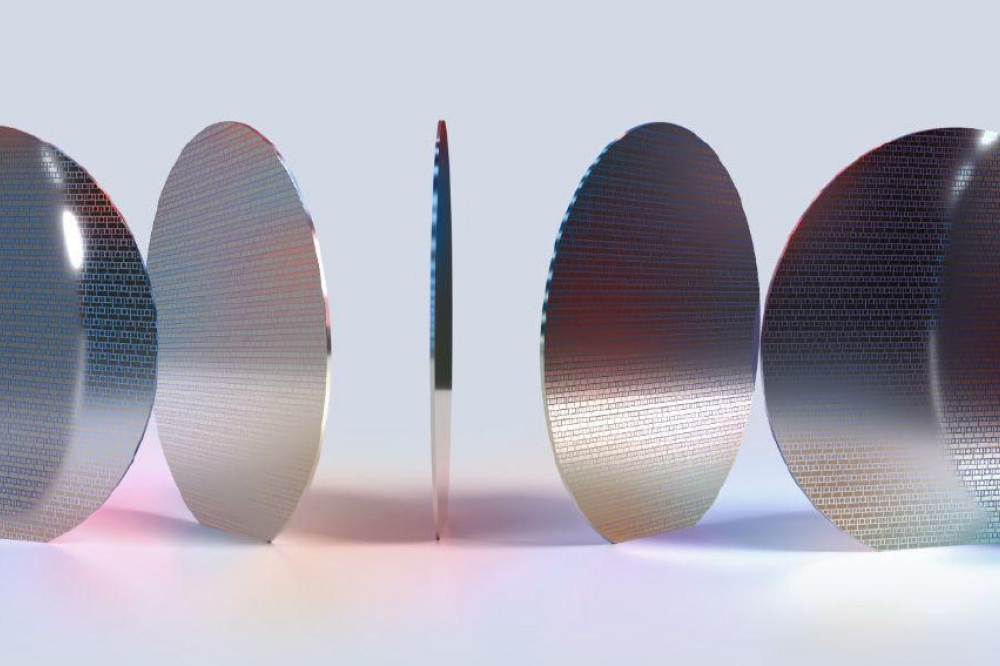

Scientists from Boston University, UC Berkeley, and Northwestern University have published a study in Nature Electronics reporting the world’s first electronic–photonic–quantum system on a chip. According to the team, the system combines quantum light sources and stabilising electronics using a standard 45 nm semiconductor manufacturing process to produce reliable streams of correlated photon pairs – a key resource for emerging quantum technologies. This development could pave the way for mass-producible “quantum light factory” chips and large-scale quantum systems built from many such chips working together.

“Quantum computing, communication, and sensing are on a decades-long path from concept to reality,” says Miloš Popović, associate professor of electrical and computer engineering at BU and a senior author on the study. “This is a small step on that path – but an important one, because it shows we can build repeatable, controllable quantum systems in commercial semiconductor foundries.”

Prem Kumar, professor of electrical and computer engineering at Northwestern, added: “The kind of interdisciplinary collaboration this work required is exactly what’s needed to move quantum systems from the lab to scalable platforms. We couldn’t have done this without the combined efforts in electronics, photonics, and quantum measurement.”

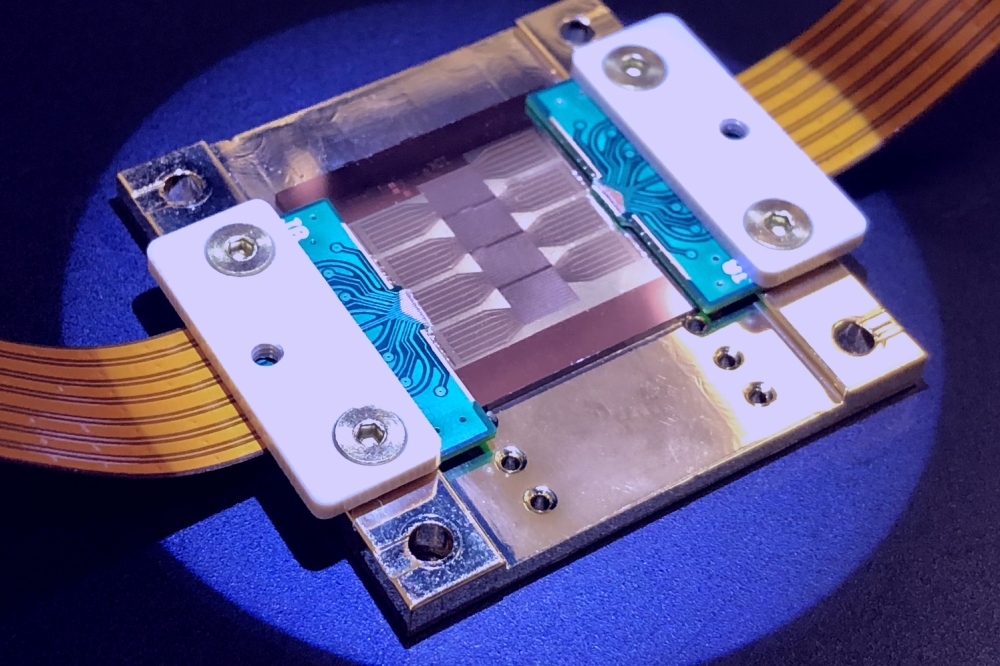

Future quantum technologies will require a steady stream of quantum light resource units to perform their functions. To provide this, the researchers worked to create an array of “quantum light factories” on a silicon chip, each less than 1x1 mm in dimension.

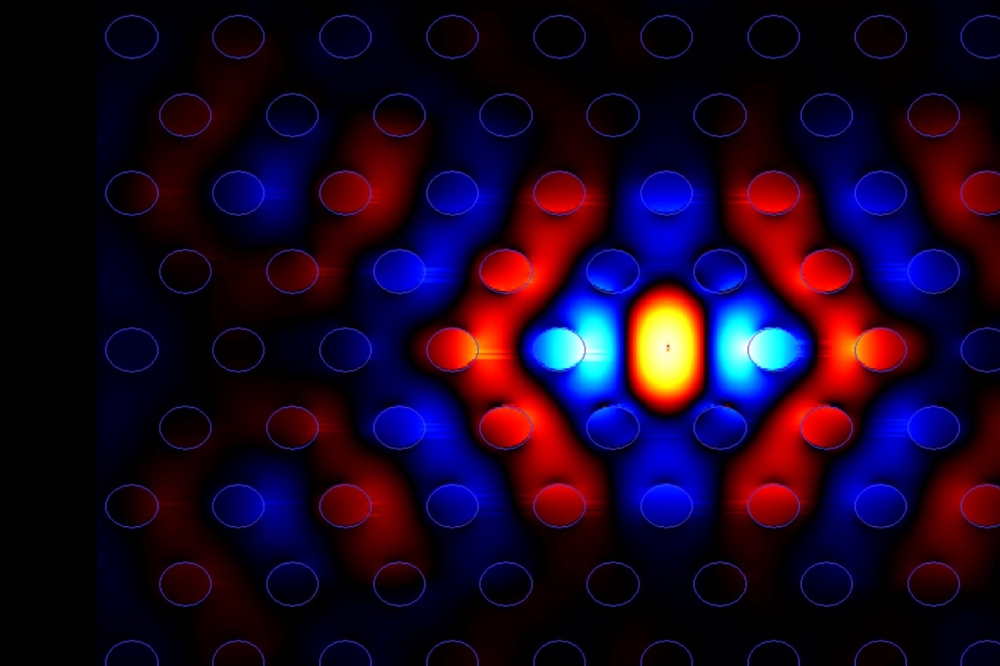

To generate streams of quantum light, in the form of correlated pairs of photons, microring resonators must be tuned in sync with incoming laser light that powers each quantum light factory on the chip. But these devices are extremely sensitive to temperature and fabrication variations, which can push them out of sync and disrupt the steady generation of quantum light.

To address this challenge, the team built an integrated system designed to actively stabilise quantum light sources on-chip – specifically, the silicon microring resonators that generate the streams of correlated photons. According to the scientists, each chip contains 12 such sources operable in parallel, and each resonator must stay in sync with its incoming laser light even in the presence of temperature drift and interference from nearby devices – including the other 11 photon-pair sources on the chip.

“What excites me most is that we embedded the control directly on-chip – stabilising a quantum process in real time,” says Anirudh Ramesh, a PhD student at Northwestern who led the quantum measurements. “That’s a critical step toward scalable quantum systems.”

The extreme sensitivity of the microring resonators is the reason why they can generate quantum light streams efficiently and in a minimal chip area, but small shifts in temperature can derail the photon-pair generation process. The new study describes how the authors solved this by integrating photodiodes inside the resonators in a way that monitors alignment with the incoming laser while preserving the quantum light generation. On-chip heaters and control logic are included to continually adjust the resonance in response to drift.

“A key challenge relative to our previous work was to push photonics design to meet the demanding requirements of quantum optics while remaining within the strict constraints of a commercial CMOS platform,” says Imbert Wang, a PhD student at Boston University who led the photonic device design. “That enabled co-design of the electronics and quantum optics as a unified system.”

Because the chip uses built-in feedback to stabilise each source, the researchers say it behaves predictably despite temperature changes and fabrication variations – an essential requirement for scaling up quantum systems. It was fabricated in a commercial 45 nm CMOS chip platform originally developed through a collaboration between BU, UC Berkeley, GlobalFoundries, and Silicon Valley start-up Ayar Labs, which grew out of research at the two universities and is now developing optical interconnect chiplets. Through the new collaboration with Northwestern, that same manufacturing process now enables not only advanced optical interconnects for AI and supercomputing, but also, according to the study, complex quantum photonic systems on a scalable silicon platform.

“Our goal was to show that complex quantum photonic systems can be built and stabilised entirely within a CMOS chip,” says Daniel Kramnik, a PhD student at UC Berkeley who led chip design, packaging, and integration. “That required tight coordination across domains that don’t usually talk to each other.”

As quantum photonic systems progress in scale and complexity, chips like this could become building blocks for technologies ranging from secure communication networks to advanced sensing and, eventually, quantum computing infrastructure.