Optiwave Systems and CPFC partner on simulation for custom III-V devices

With the OptiSystem simulation framework, the organisations aim to address the lack of a supporting simulation ecosystem associated with pure-play foundries, enabling clients to tighten design cycles and reduce time to market

Optiwave Systems and the National Research Council of Canada‘s Canadian Photonics Fabrication Centre (CPFC) are collaborating to deliver a design-to-manufacturing workflow that enables fabrication-aware simulation of custom III-V devices while protecting both epitaxial and layout design IP.

The advancement in heterogeneous PICs has evolved to a level that requires a unified simulation environment that enables pre-manufacturability evaluation. A high-fidelity simulation environment offers a distinct competitive advantage by drastically reducing a product’s time to market and enhancing product quality through low-cost parameter exploration, thus improving overall cost-effectiveness and competitiveness.

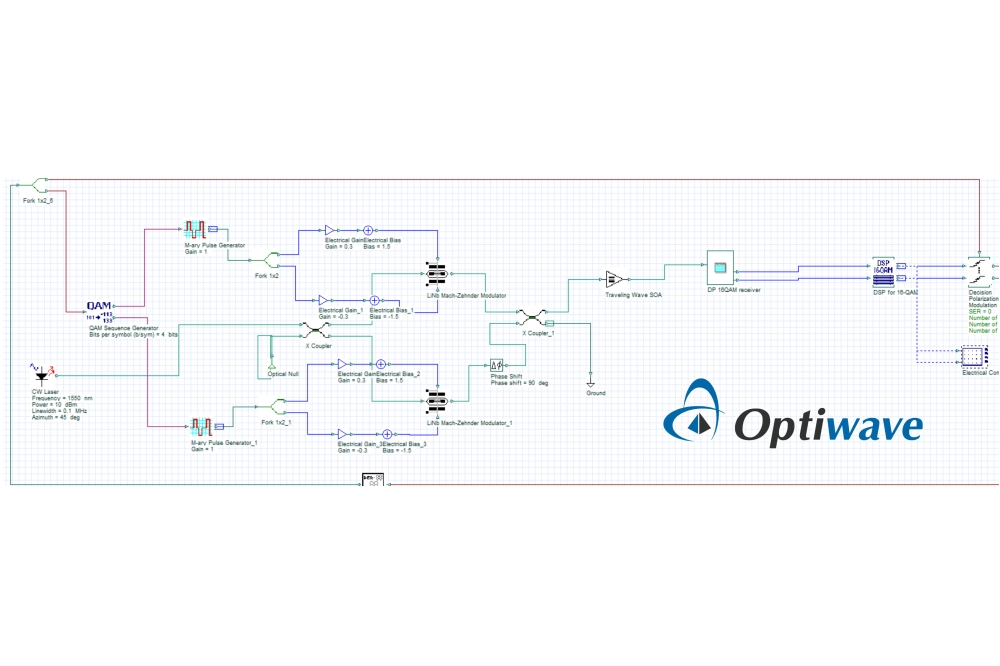

Optiwave Systems offers a comprehensive solution for designing PICs from schematic design to system characterisation. The company says its monolithic simulation platform includes SPICE and System software that seamlessly integrates with third-party software for loading process design kits (PDKs) from photonic fabrication facilities. Compact device models (CDMs) of commercial PDKs can be generated using Optiwave’s OptiFDTD and OptiMode software, then applied to the OptiSPICE engine called by layout tools. The company adds that OptiSystem also enables the characterisation of a PIC’s performance within a system comprising devices, optical wires or wireless channels.

The CPFC is a commercial pure-play indium phosphide (InP) photonics foundry that specialises in volume manufacturing of custom high-performance devices, such as buried heterostructure lasers and optical amplifiers.

In a design-assisted III-V foundry model, a foundry provides a set of reference designs, or PDKs, to allow clients to rapidly construct photonic circuits. In contrast, with the pure-play III-V foundry model, clients specify both component geometries and epitaxial compositions. The resulting photonic devices fabricated at pure-play foundries are thus fully customised and capable of achieving best-in-class performance tailored for specific applications.

One challenge in the pure-play foundry model arising from the lack of III-V component standardisation is the absence of a supporting simulation ecosystem for custom photonic devices. Optiwave Systems and the CPFC are aiming to address this challenge, by delivering a design-to-manufacturing workflow that enables fabrication-aware simulation of custom III-V devices while protecting both epitaxial and layout design IP.

The organisations say that clients working with both Optiwave Systems and the CPFC can leverage this workflow to fabricate custom III-V devices with the CPFC and emulate their performance in system-level and link-level deployments with OptiSystem’s suite of over 600 components, including realistic fibre models, DSP components, and advanced visualisers.

Moreover, the heterogeneous integration of III-V materials onto silicon platforms has attracted significant attention in the past year. According to Optiwave, its complementary suite of simulation tools allows users to evaluate custom III-V components fabricated at the CPFC with various silicon photonics technologies, such as those accessible in PDK form at various silicon foundries.

The organisations say that, through their partnership, silicon foundries can provide mutual clients with a monolithic design and simulation framework for custom heterogeneous photonic systems. By leveraging these new capabilities, they aim to enable clients to tighten design cycles and reduce errors on the road to volume manufacturing of heterogeneous systems.

Image credit: Optiwave Systems Inc.