SWIR photodetectors made of eco-friendly colloidal quantum dots

Researchers describe a new technique for fabricating colloidal quantum dots free of heavy metals and stable under ambient conditions, which could be used in applications from LiDAR to virtual reality

Researchers from ICFO – The Institute of Photonic Sciences have developed a novel method for synthesising indium antimonide (InSb) and indium phosphide (InP) colloidal quantum dots (CQDs) that are stable under ambient conditions. In the journal ACS Nano, they report that they have employed these quantum dots to fabricate a fast and highly sensitive arsenic-free short-wave infrared (SWIR) light sensor. The scientists say this new technique expands the possibility for the fabrication of optoelectronic devices based on environmentally friendly CQDs, compliant with the current regulations around their commercial use.

Applications such as LiDAR, automotive, and augmented reality/virtual reality, rely on the development of SWIR photodetectors, which can see in the spectral window of 1-2 µm, a region invisible to our eyes. The SWIR light sensor industry has been dominated for years by epitaxial technology, mainly based on devices made of indium gallium arsenide (InGaAs). However, this technology has several drawbacks, such as high production costs, low-scale manufacturability, and incompatibility with CMOS.

SWIR photodetectors made of CQDs, nanoscale semiconductor materials, have attracted significant interest in recent years due to their low cost and compatibility with CMOS architecture, among other advantages. However, current CQD-based SWIR photodetectors use components such as lead and mercury chalcogenides, which are subject to the Restriction of Hazardous Substances (RoHS) European directive, which regulates their usage in commercial consumer applications.

There is therefore a pressing urge for the development of SWIR light sensors based on environmentally friendly, CQDs free of toxic heavy metals. One potential alternative material is InSb, but its synthesis has so far proven challenging due to its strongly covalent nature and lack of highly reactive precursors. Studies have also reported that InSb CQDs are unstable upon exposure to air due to the strong propensity of Sb to oxidise.

In a new study published in ACS Nano, researchers from ICFO and Erns Ruska Centre for Microscopy and Spectroscopy with Electrons, describe a novel method to synthesise arsenic-free InSb CQDs with access to the SWIR range. The scientists say this new technique can produce high-quality wide spectral tuneable InSb quantum dots with size uniformity by using commercially available chemical precursors, overcoming some of the hurdles that previous strategies had suffered, including a challenging synthesis process and high surface defect density.

In their study, the researchers adopted the “single-source approach”, using a continuous precursor injection process, instead of a hot injection option. This strategy was key to obtain InSb CQDs with a well-controlled size distribution and distinct absorption over a very broad range of the spectrum (900 nm to 1750 nm). By using a range of reaction temperatures spanning from 220-250 degrees Celsius, they were able to control the positions of the dots within the resulting solution-processed thin film. “The resultant spectral tuneability from near-infrared to short-wave infrared, that is from 900 nm to 1750 nm, is the largest reported to date for InSb CQD,” the researchers said.

The researchers also developed a passivation strategy to cover the obtained InSb CQDs, creating a shell to protect them from oxidation. To do this, they treated the surface of the InSb QCDs with indium trichloride, and then grew a thin InP protection shell over the purified InSb CQD.

“InSb/InP core-shell structure means growing another material (in this case, InP) on the surface of the pristine material (in this case, InSb),” explains Lucheng Peng, ICFO researcher and first author of the study. “In comparison to InSb, InP is a wider bandgap material that can sufficiently passivate the surface traps of InSb that are detrimental in optoelectronic devices. Also, the Sb element is quite sensitive to oxygen, so the core-shell structure can largely improve the air stability of the material.”

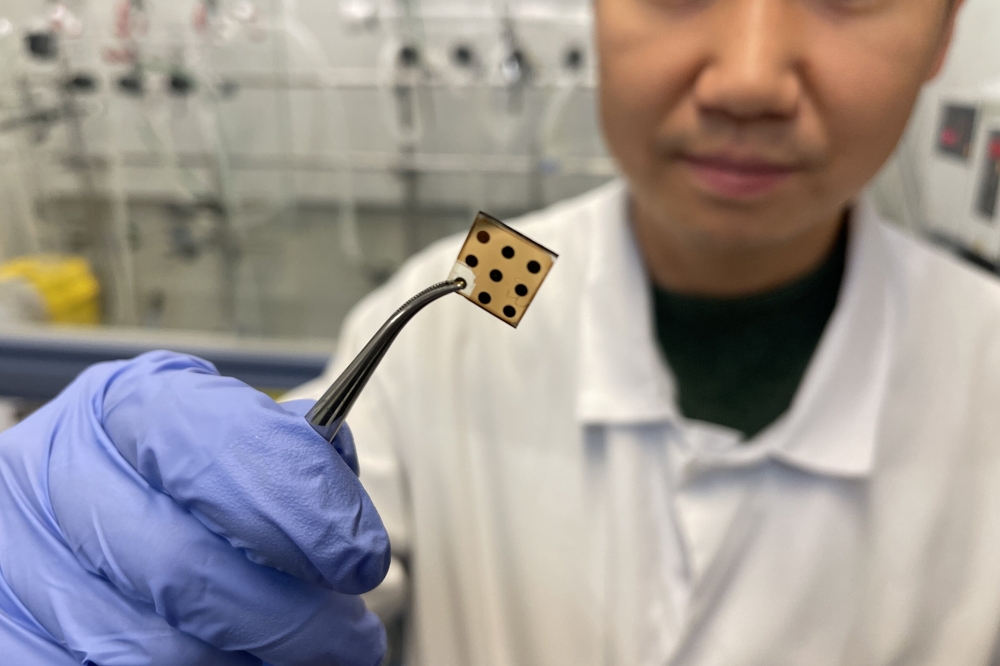

Fabricating photodetectors

Next, the researchers moved onto using the optimised InSb/InP core-shell CQDs to fabricate a low-temperature, high-speed SWIR photodetector formed of several stacked layers: a base of indium tin oxide, an electron transfer layer made of titanium dioxide, the thin layer containing the InSb/InP CQDs and a final top layer made of gold.

The scientists found that the photodetector “demonstrates remarkable features including a wide linear dynamic range exceeding 128 dB, a maximum external quantum efficiency (EQE) of 25 percent at 1240 nm (and 12 percent at 1420 nm), fast photoresponse time of 70 ns, and a specific detectivity of up to 4.4 × 1011 Jones.”

According to the scientists, the device also turned out to be highly resistant to atmospheric conditions without any encapsulation; after two months of exposure to the ambient environment, the photodetector maintained its properties. After 90 hours, the device's stability was also verified when it was functioning in the open air, and it was found to be extremely stable.

“This is the best solution-processed, CQD SWIR photodetector based on InSb so far considering both performance and stability, with figures of merit that can enable high-frame-rate light sensors for machine vision, gated imaging and 3D sensing applications,” said Gerasimos Konstantatos, a professor at ICFO who led the research. “The present study not only shows the enormous potential of InSb CQDs as an active material free of heavy metals to be used in SWIR photodetectors, but it also opens the door for future developments in colloidal InSb utilising wet chemical methods towards the fabrication of high-performing electronic or optoelectronic devices.”

Image credit: ICFO