Corrugated micro-ring generates specific wavelengths of light

Image credit: S. Kelley/NIST

Scientists have published a paper in Nature Photonics, reporting that they have converted near-infrared (NIR) laser light into specific desired wavelengths of visible light with high accuracy and efficiency. This precise control was achieved through the addition of corrugations to a micro-ring resonator. The work was done by researchers at the National Institute of Standards and Technology (NIST) and their colleagues at the Joint Quantum Institute (JQI), a research partnership between the University of Maryland and NIST.

The technique has potential applications in precision timekeeping and quantum information science, which require highly specific wavelengths of visible laser light that cannot always be achieved with diode lasers (devices akin to LED lights) to drive atomic or solid-state systems.

Ideally, the team says that the wavelengths should be generated in a compact device, such as a photonic chip, so that quantum sensors and optical atomic clocks can be deployed outside the laboratory, no longer tethered to bulky optical equipment.

In previous experiments, NIST researcher Kartik Srinivasan and his colleagues used perfectly smooth micro-resonators – ring-shaped devices with a diameter about one-quarter the thickness of a human hair – to transform a single wavelength of NIR light into two other wavelengths. The resonator, small enough to fit on a microchip, can be designed so that one of the two output wavelengths falls within the spectrum of visible light. The transformation occurs when the NIR laser light, confined to circle the ring-shaped resonator thousands of times, reaches intensities high enough to strongly interact with the resonator material.

In theory, by choosing the resonator’s radius, width and height – which determine the properties of the light that can resonate in the ring – researchers can select any among a rainbow of colours possible with the technique. In practice however, the method, known as optical parametric oscillation (OPO), is not always precise. Even deviations as small as a few nanometres from the specified dimensions of the micro-ring produce visible-light colours that differ significantly from the desired output wavelength.

As a result, researchers have had to fabricate as many as 100 of the silicon nitride micro-rings in order to be confident that at least some would have the right dimensions to generate the target wavelength. But even that laborious measure does not guarantee success.

Now, Srinivasan and his collaborators, led by Jordan Stone of JQI, have reported that by introducing imperfections – tiny, periodic corrugations, or bumps – along the surface of a micro-resonator they can select a specific output wavelength of visible light to an accuracy of 99.7 percent. With improvements, Stone said, the technique should produce visible-light wavelengths accurate to better than 99.9 percent of their target values, a requirement for powering optical atomic clocks and other high-precision devices.

“In our previous experiments, we reached the general range of a wavelength of interest, but for many applications that isn’t good enough. You really have to nail the wavelength to a high degree of accuracy,” said Stone. “We now achieve this accuracy by incorporating a periodic arrangement of corrugations on a micro-ring resonator.”

How the corrugated micro-ring resonator works

The principle that governs the optical transformation of a single-wavelength input into two outputs of different wavelengths is the law of conservation of energy: The energy carried by two of the input photons from the near-infrared laser must equal the energy carried by the output photons: One with a shorter wavelength (higher energy) and one with longer (lower energy) wavelength. In this case, the shorter wavelength is visible light.

In addition, each of the input and output wavelengths must correspond to one of the resonant wavelengths permitted by the dimensions of the micro-ring, just as the length of a tuning fork determines the one specific note at which it resonates.

In their new study, the researchers designed a micro-ring whose dimensions, without corrugations, would not have allowed the photons to resonate in the ring and produce new wavelengths because the process would not have conserved energy.

However, when the team sculpted the ring with tiny, periodic corrugations, altering its dimensions, it allowed OPO to proceed, transforming the NIR laser light into a specific wavelength of visible light plus one other, much longer, wavelength. These OPO-generated colours, unlike those previously created by smooth micro-rings, can be precisely controlled by the spacing and width of the bumps.

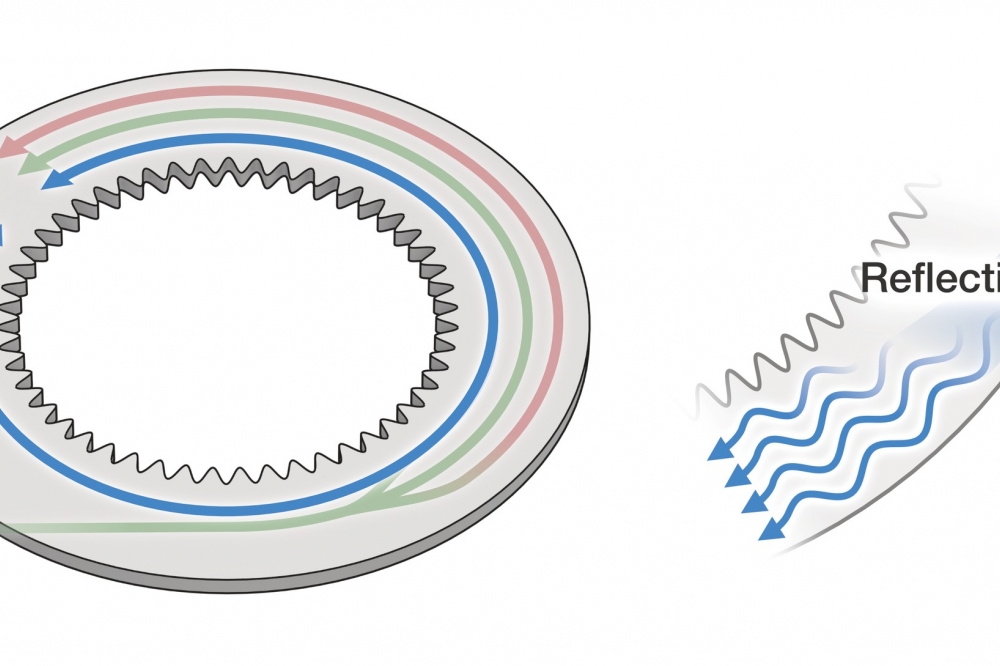

The corrugations act like tiny mirrors that collectively reflect back and forth visible light racing around the ring—but only for one particular wavelength. The reflections result in two identical waves traveling around the ring in opposite directions. Inside the ring, the counterpropagating waves interfere with each other to create a pattern known as a standing wave—a waveform whose peaks remain fixed at a particular point in space as the wave vibrates, like a plucked guitar string.

This translates into a shift towards a longer or shorter wavelength, depending on whether the standing wave interacts more with the peaks or troughs of the corrugations. In both cases, the magnitude of the shift is determined by the height of the bump. Because the bumps only act as a mirror for a specific wavelength of light, the approach guarantees that when OPO occurs, the generated signal wave has the exact desired wavelength.

By slightly altering the wavelength of the infrared laser that drives the OPO process, any imperfections in the corrugations can be compensated for, Stone said.