Stäubli Award goes to robotics system for assembling photonic modules

Robo-Technology has received the Stäubli Robotics Award at this year's Stäubli Partner Summit. The Swiss company awards the prize every other year for unique achievements in the automation sector. The sole criterion is the degree of innovation of solutions utilising Stäubli robots.

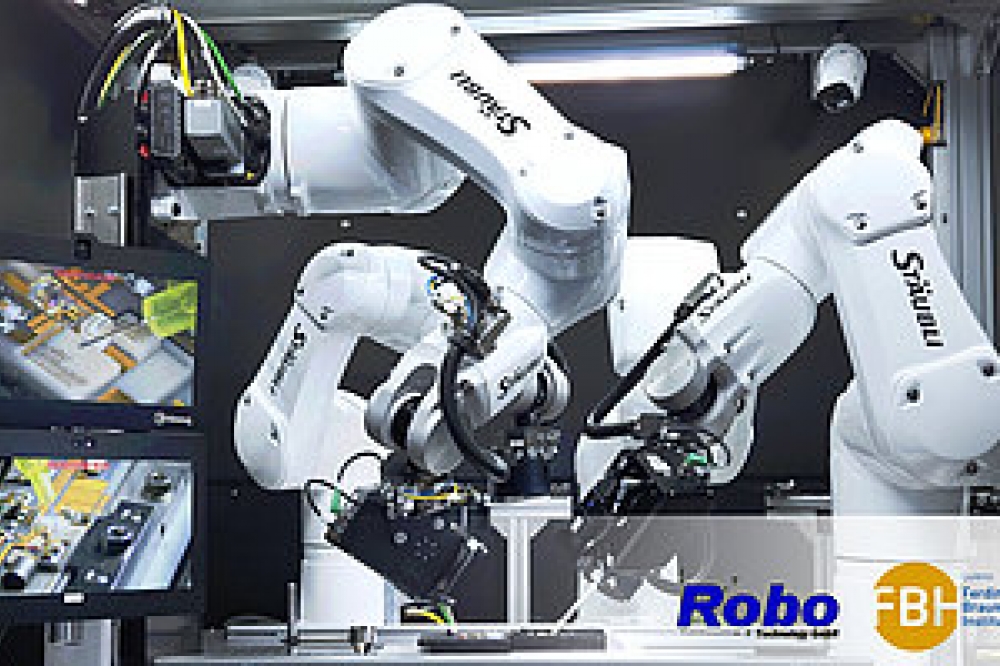

The award went to Robo-Technology’s “Microbot” – a collaborative robotic system developed to assemble complex photonic modules with utmost accuracy. The robust modules developed and manufactured by the Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) are designed to be intuitive to operate and are used in space and quantum technology applications.

The system concept was jointly developed by FBH and Robo-Technology, who say it is tailored entirely to support the human operator, using a wide variety of Industry 5.0 elements and combining the experience and know-how of a human operator with the advantages of robotics. For example, many steps that had to be executed manually by human operators are taken over by robots, so that extreme spatial precision can be maintained for many hours.

According to FBH and Robo-Technology, the Microbot system is therefore ideally suited to assembling FBH’s highly complex photonic modules for research purposes as well as for pilot and small series production. The institute and company say that, for the first time ever, the novel collaborative robotic facility enables industry-compatible production of highly complex hybrid micro-integrated photonic modules for use in quantum sensing and quantum computing.

Andreas Wicht, head of the FBH’s Joint Lab Quantum Photonic Components is enthusiastic about the cooperation: “Actually, we had expected that our ideas could not be implemented. We were impressed by how quickly and precisely the colleagues at Robo-Technology picked up our requirements and developed them into a joint vision. The quality of the robotic solution would have been unattainable without Robo-Technology's very broad portfolio of expertise, ranging from concept development through CAE-supported mechanical design, electrical and electronic control hardware development to software development and implementation of complex safety concepts.”

Robo-Technology has planned and implemented the robotic system including the control hardware and software. It has also developed various tools for the Stäubli robots according to the process requirements.

"In order to be able to develop this highly complex facility, the very precisely defined technical requirements of our partner FBH and its visions for the intuitive control concept were indispensable," explains Jürgen Bosse, Managing Director of Robo-Technology. "Together, we succeeded in realising a system that takes the assembly of miniaturised modules a big step forward from the laboratory towards industry."