Brewer Science and PulseForge Bring Photonic Debonding to Advanced Packaging

Brewer Science, Inc. and PulseForge, Inc. bring substantial cost savings, increased throughput, and other benefits with photonic debonding to semiconductor advanced packaging. This collaboration combines a global leader in manufacturing next-generation materials and processes with a unique technology provider.

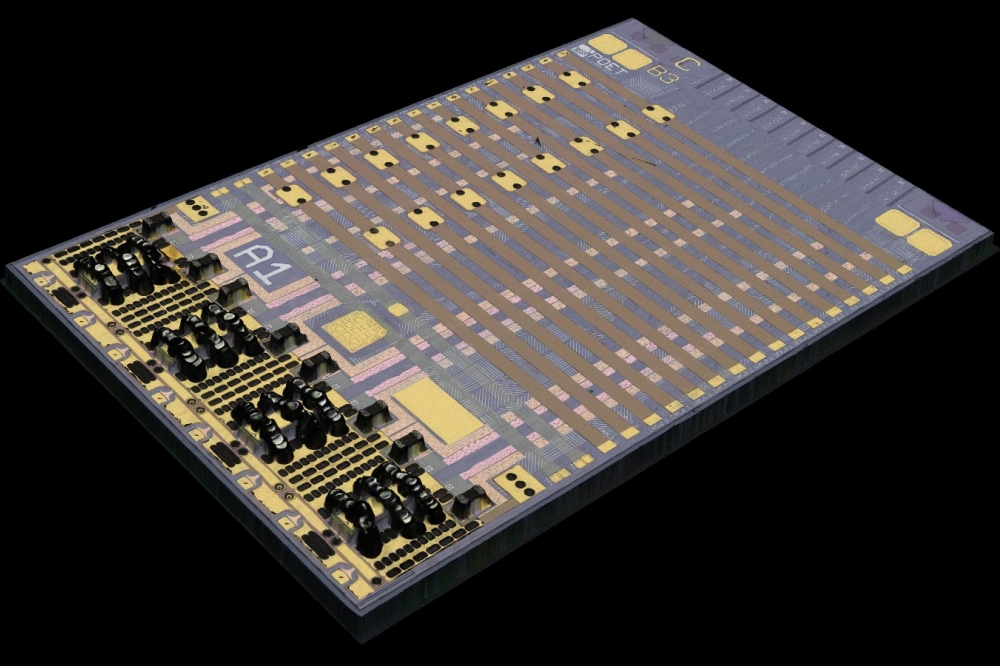

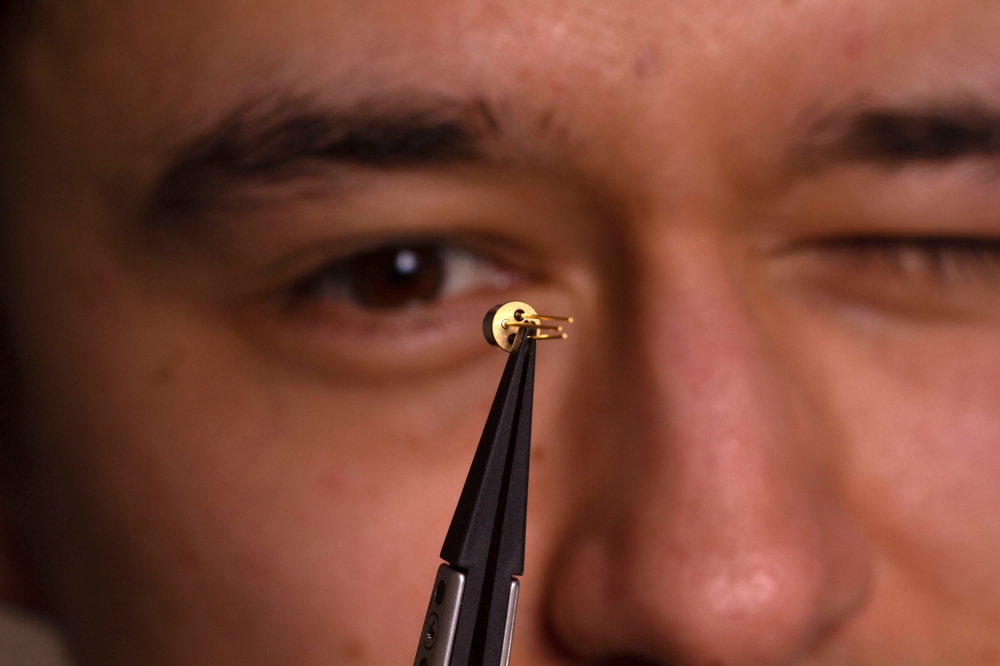

Photonic debonding is a revolutionary technology that uses high-intensity pulses of light in conjunction with a proprietary inorganic light-absorbing layer to debond temporarily bonded wafer pairs. Photonic debonding using Brewer Science BrewerBOND series materials enables back-end-of-line processing of ultrathin wafers. Collectively, PulseForge and Brewer Science offer a unique photonic debonding wafer support system suitable for advanced packaging applications.

Photonic debonding provides a substantially lower cost of ownership over incumbent industry alternatives. Photonic debonding can process warped wafers without requiring expensive and time-consuming warpage adjustment hardware. Photonic debonding is the first to introduce a reusable inorganic release layer, resulting in a clean, ash-free debonding process.

Brewer Science and PulseForge are co-presenting Photonic Debonding for Wafer–Level Packaging at CS MANTECH on Thursday, May 18 at 2:40 pm (Session 18). Additionally, Brewer Science is a gold sponsor and will exhibit at booth 224 throughout the duration of CS MANTECH, May 15 through May 18, 2023. You can also learn more about Brewer Science on May 16th at 5:40pm during Session 3: Thin films & materials in Grand Cypress G.