New Technology Enables Machined Optical Glass

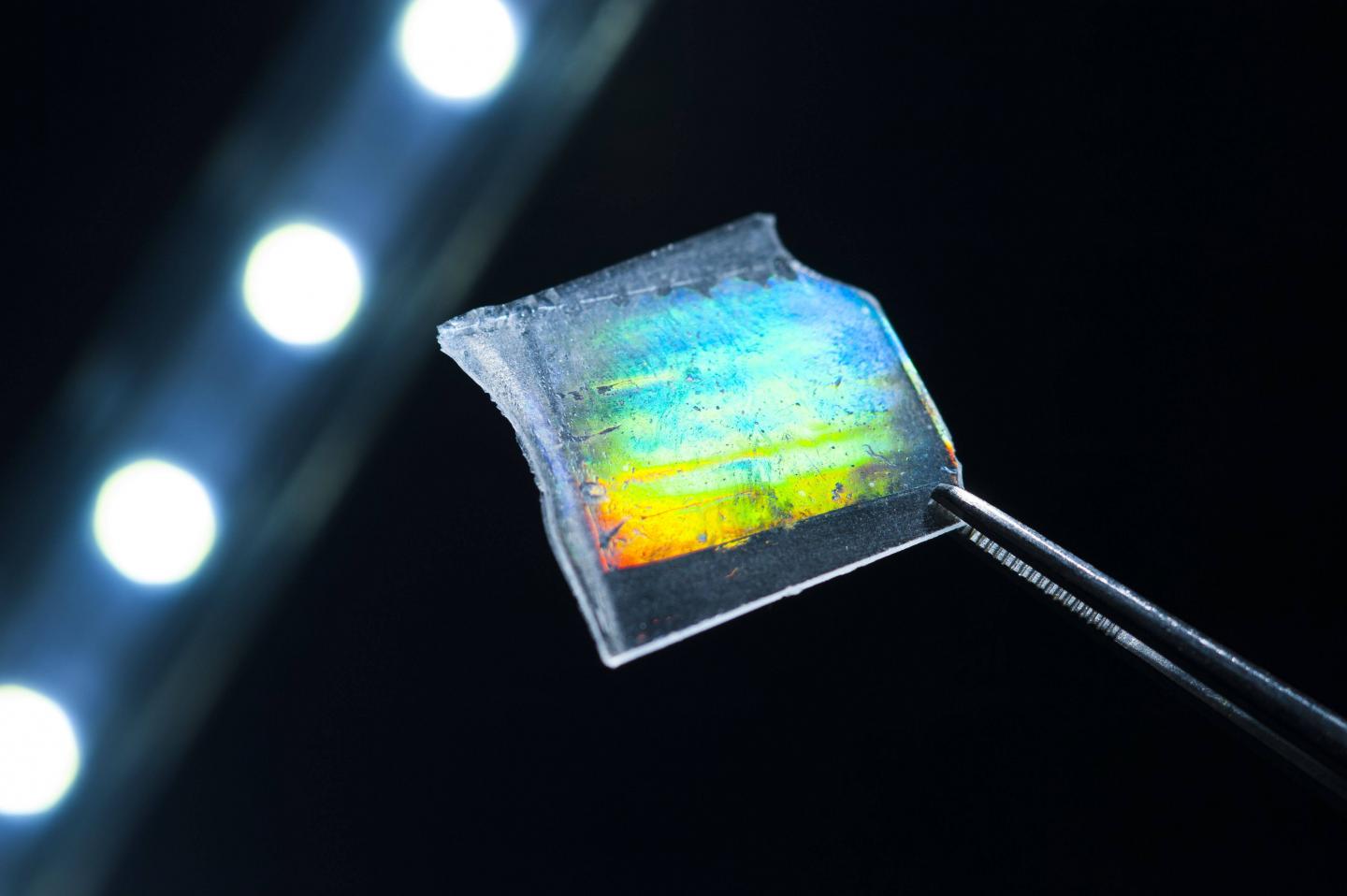

Researchers at the Karlsruher Institute of Technology (KIT)

have announced the creation of a new optical glass that can be milled, turned,

lasered or processed in computer numeric control (CNC) machines just like a

conventional polymer. Image courtesy of Markus Breig/KIT.

A new technology developed at the Karlsruher Institute of Technology (KIT) in Germany could make it possible to produce and use high-quality glass materials in place of polymers, the researchers have reported. The innovation, known as Glassomer, could be used in optical, photonic, medical, and industrial applications.

Glassomer is a solid nanocomposite that can be structured using polymer molding and subtractive technologies at submicrometer resolution. After polymer processing, Glassomer is turned into optical-grade fused silica glass during a final heat treatment. According to its inventors, the resulting glass has the same optical transparency as commercial fused silica and a smooth surface with a roughness of a few nanometers.

Scientists at KIT mixed glass particles, 40 nm each, with a liquid polymer. The mix can be hardened to a solid through heating or exposure to light. The resulting solid consists of glass particles in a matrix at a ratio of 60 to 40 volume percent. The polymer acts like a bonding agent, maintaining the matrix of glass particles and thus the shape of the material.

For fabricating high-performance lenses, the researchers produce a Glassomer rod, from which the lenses are cut. For highly pure quartz glass, the researchers remove the polymers in the composite by heating the lenses in a furnace at 500 to 600 °C, causing the polymer to be burned to CO2. Then, to close any gaps in the material that result from this process, the lenses are sintered at 1300 °C. During the sintering process, the remaining glass particles are densified to pore-free glass.

Glassomer can be milled, turned, laser-machined, or processed in computer numeric control (CNC) machines just like a conventional polymer.

"The entire range of polymer-forming technologies is now opened for glass," said Bastian E. Rapp, head of NeptunLab at KIT's Institute of Microstructure Technology.

This advance in materials processing could make high-performance fused silica glass components accessible to high-throughput fabrication technologies.

"Our process is suited for mass production. Production and use of quartz glass are much cheaper, more sustainable, and more energy-efficient than those of a special polymer," said Rapp.

There are plans to commercialize Glassomer.