UK scientist 3D prints optical fibres

Southampton postgrad is using silicon oxide powder to 3D print optical-quality glass for optical fibres, planar wave guides, and other devices

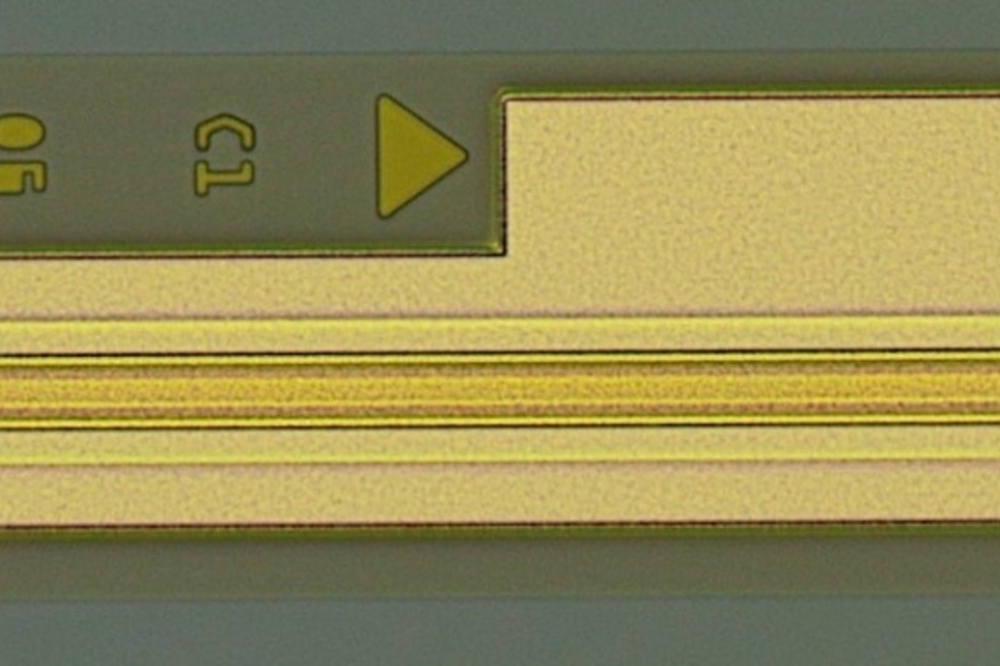

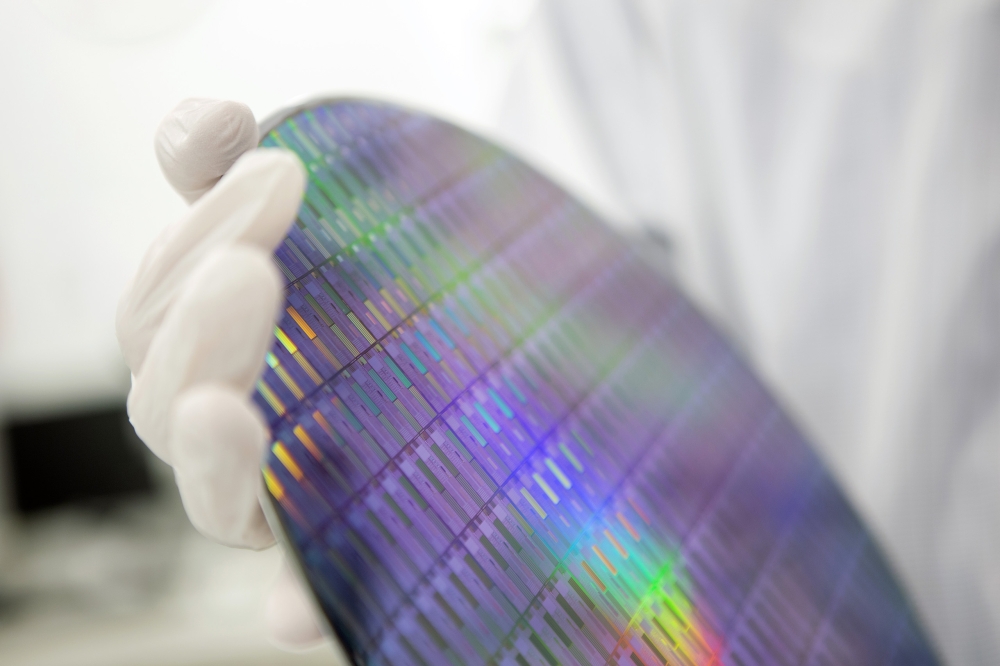

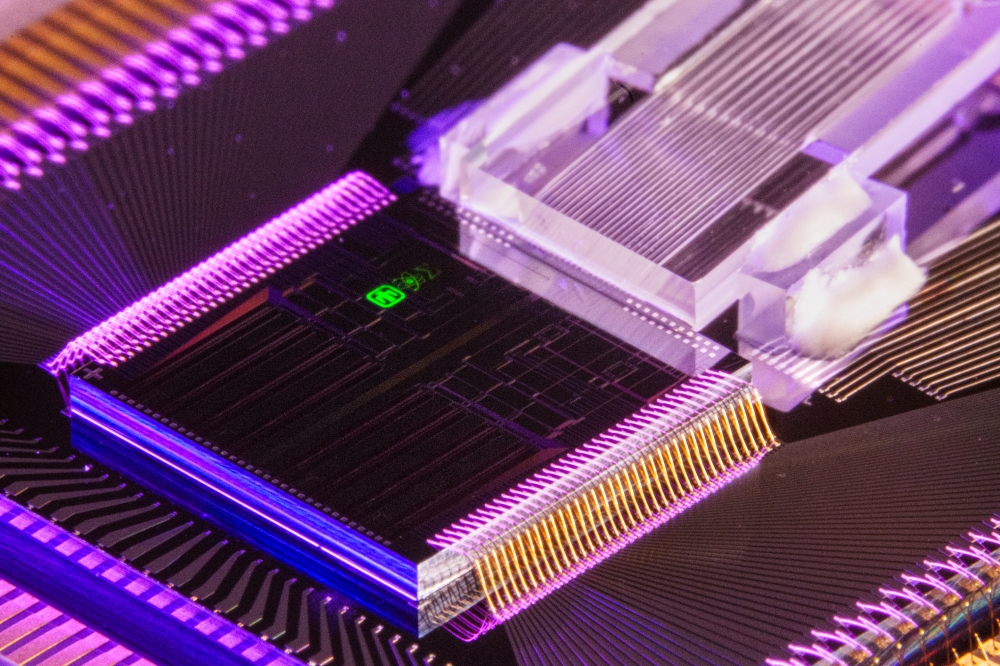

Angeles Camacho Rosales, a postgraduate research student at the University of Southampton's Optoelectronics Research Centre in the UK, is developing ways to 3D print glass for optical fibres.

According to an article in www.3ders.org, she is using silicon oxide powder to 3D print optical-quality glass for optical fibres, planar wave guides, and other devices.

Understanding the relationship between the 3D printable materials and light is a key challenge in the research, since the material's absorption and reflection, as well as its capacity to propagate light and tendency to change under laser beam exposure, ultimately affecting how the 3D printed glass turns out.

Rosales thinks 3D printed glass may be the only option for producing the kind of highly complex optical fibre designs required for the next generation of data transmission technologies.

An additive manufacturing approach to optical glass production will also researchers to experiment with different optical designs, immediately seeing which are successful in the transition of information. Once a prototype is 3D printed, the fibre design can be subjected to physical testing regarding losses, data transmission, and propagation modes.

"Currently, when an optical fibre is designed, it often remains only as a prototype or computer simulation because in certain cases it is very difficult or even impossible to produce those designs," Rosales explains. "With this new method, these exceptional designs could be realised, transforming telecommunications as we know it."