PICs: a little piece of glass can change everything

How can you improve the coupling efficiency between optical fibres and photonic integrated circuits? Florent Gardillou -- technical project leader and business development manager at Teem Photonics -- takes a detailed look at the latest transposer technology and its application in silicon photonics-based designs, as well as reviewing the firm's broader activity in advancing PICs.

In the past years, silicon photonics (SiP) has captured the attention of the photonics integrated circuit (PIC) community by offering a compact and highly scalable solution across a range of applications. But there are technical issues to contend with. The main downside of SiP waveguides' high-confinement feature is the poor coupling efficiency when interfacing with optical fibres. Indeed, the typical cross section of a silicon waveguide (0.5 x 0.3µm) is more than 300 times smaller than the core of standard optical fibres (8µm diameter).

The « top coupling » solution has raised great hope over the last decade. The principle is to illuminate, from the top surface, a grating coupler integrated on the silicon chip through a nearly vertical fibre. But, despite the huge effort made by many groups over the world on this topic, this solution does not appear to lead to a consensus, at least for future high-performance components.

The main reasons are :

a coupling efficiency that remains low (especially for the two-polarisations coupling configuration),

the dispersive principle of grating couplers that still limits the operating bandwidth to 30-40nm,

a poor packaging compactness due to fibres disposed vertically with respect to the chip surface.

As a result, « edge coupling » configurations are back in contention, helped by the integration of « edge couplers » on SiP chips. The spot size converters (SSC) and the inverted tapers allow an adiabatic transition from a sub-micronic mode field diameter (MFD) to larger ones, available with lensed optical fibres (MFD 2.5-4µm @ 1550nm).

But lensed fibres present several drawbacks for SiP chip coupling. First of all, ensuring a stable coupling efficiency packaging with lensed fibres still remains challenging. Moreover, the realisation of lensed fibres array for the coupling of the future multi-channels components is compromised by:

the difficulty to ensure a good fibre pitch homogeneity

the limitation of the fibre pitch to 127µm that undermines SiP chip compactness

the low-scalability of the solution

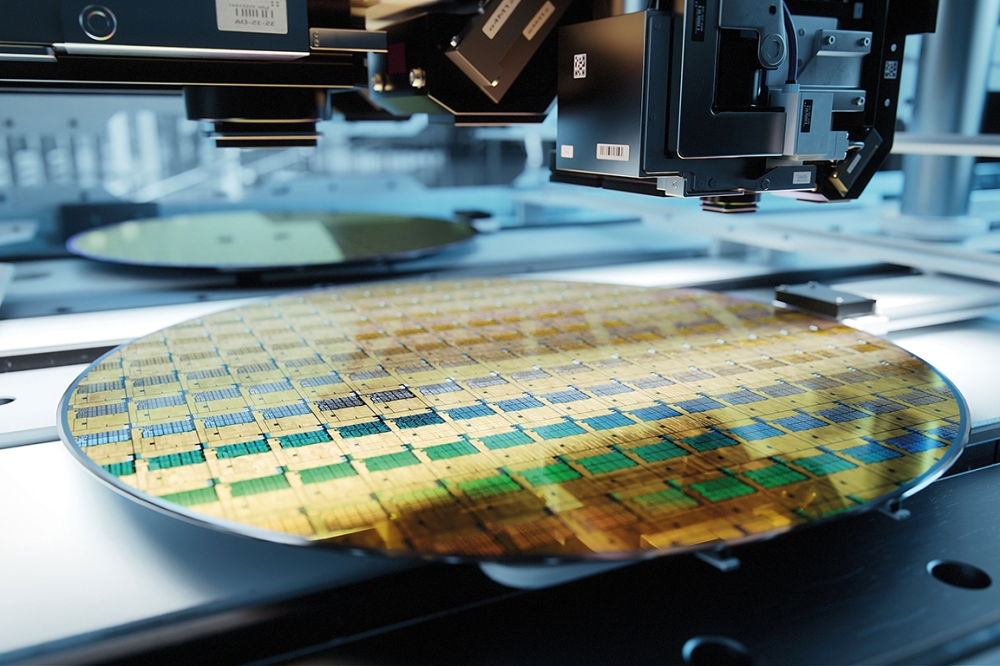

WAFT : the glass optical transposer for SiP connection

Based on its ioNext platform for the manufacturing of photonic integrated circuits on glass, Teem Photonics has recently developed a new optical transposer component for edge coupling to tackle these issues.

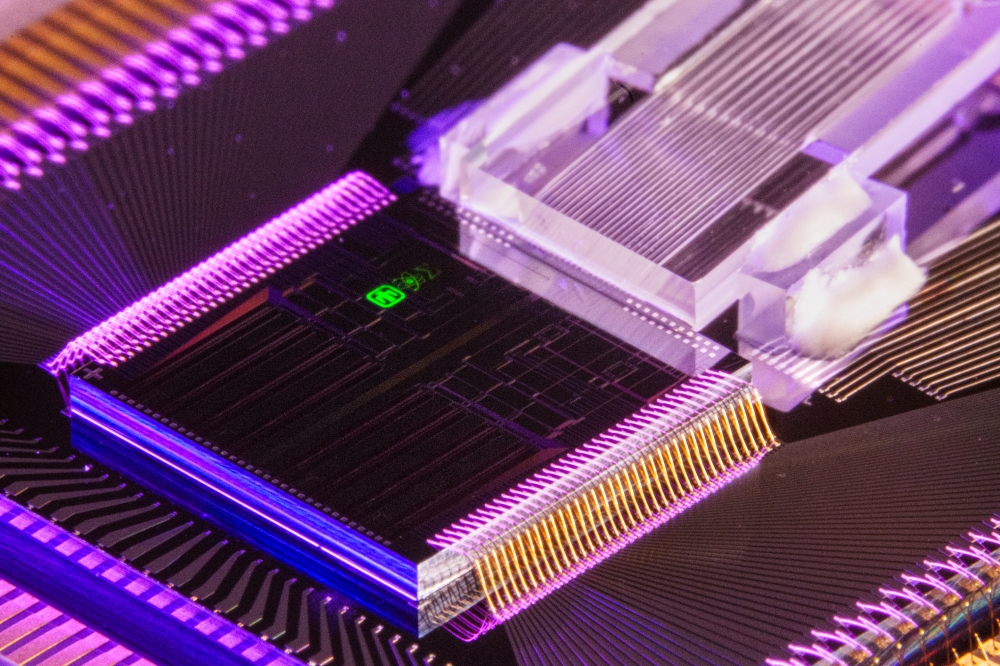

Figure 1. Principle of the WAFT component which combines a fibre spacing concentrator (FSC) and an array of mode converter waveguides

As illustrated above, the WAFT (waveguides array to fibre transposer) is combining an array of mode converter waveguides with a fibre spacing concentrator (FSC). The mode converters that are integrated on the WAFT component enable a good correspondence to the tapered waveguide MFD of the SiPhotonics chips. Indeed, they provide a smooth transition from the MFD of a standard fibre to a much tighter one. Then, the FSC provides an optical pitch reduction down to 10µm which shrinks the area dedicated to the optical coupling on the SiP chip and therefore also induces a real cost saving.

The implementation of the ioNext platform for the manufacturing of the WAFT components provides many key features for the fibre-to-silicon-chip connection:

Highest coupling efficiency:

The ioNext optical waveguides are characterised by high coupling efficiency with standard optical fibre (< 0.2dB) and low propagation loss (< 0.1dB/cm). Additional loss due to the MFD conversion in the WAFT is limited to 0.2-0.3dB. As a result, WAFT insertion loss can be lower than 0.5dB for a 8-channel component and lower than 1dB for a 256-channel component.

The MFD of mode converter output waveguide can be fitted to inverted tapers integrated on SiP chip to minimise the glass chip/SiP chip coupling loss. Currently, we can provide an MFD as low as 4 x 3µm @ 1550nm and 1310nm which proves efficiently interfacing with current output mode profiles of SiP chips. Further tightening options of the MFD are being developed.

Compatibility with compact and robust packaging

The WAFT solution is compact.

For example, the dimensions of 10-channel (fig 2-a) and 64-channel (Fig2-b) components are only 7 x 3.7 x 2.3mm and 9.5 x 9 x 2.3mm respectively.

This is due to the reduced length of the adiabatic transition (<3mm) and an optical confinement enabling waveguides minimum bending radius as low as 1mm.

The footprint of the glass component can be reduced even more by shaping the exit of the chip as shown below (Figure 2-c). Moreover, the direct attachment between the WAFT chip and the SiP chip provides more stable and robust packaging.

Figure 2. examples of WAFT products: (a) 10-channel WAFT attached with a PM fibres array unit, (b) 64-channel WAFT attached with a SMF fibres array unit and a SiP chip. The WAFT chips can be shaped in many ways to reduce the footprint on the SiP chip side (c).

Compatibility with multi-channel components

The ioNext platform is based on a planar integrated optics technology on glass with a single lithography step. It provides high manufacturing yield that facilitates the integration of a high number of waveguides (up to 256). Moreover, the photolithography guarantees both input and output pitches accuracy better than 50nm, which is a key issue to ensure the homogeneity of the coupling efficiency from port-to-port. Finally, WAFT chip can be easily connected to standard fibres array units (FAU) with a high number of channels.

Polarisation-insensitive component

ioNext waveguides presents very low polarisation dependent loss (PDL) and high polarisation extinction ratio (PER). The input MFD of WAFT can be easily adjusted to the one of polarisation-maintaining (PM) fibres.

Scalability and high-integration level

The ioNext platform is intrinsically highly-scalable. It also offers a wide portfolio of passive optical functions that can be further integrated on the WAFT chip without high additional loss.

The main features of the WAFT components are detailed below.

Table 1. A list of WAFT component features. The parameters indicated with * are to be considered without the additional connectors loss.

Principle and portfolio

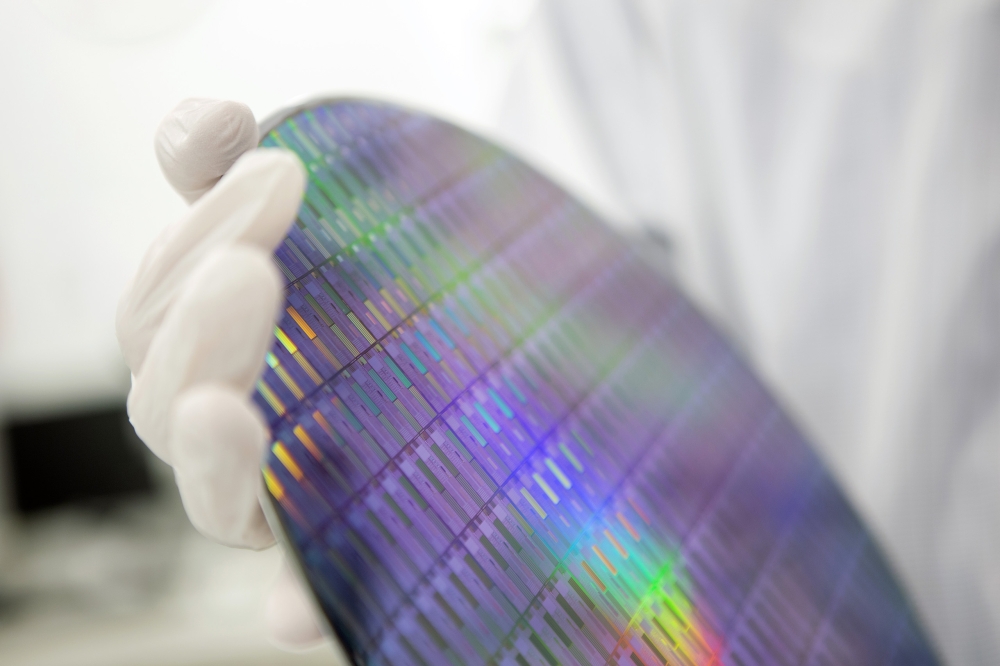

Glass is one of the best materials for guiding light in many applications thanks to its high-transparency from visible to near-infra red wavelengths. The realisation of optical waveguides in glass can be performed by an ion-exchange phenomenon associated with standard layer deposition and lithography methods. This phenomenon allows the composition of the glass to be modified locally by exchanging ions with an outer source. As refractive index and composition are closely tied, this results in the creation of optical waveguides with graded-index profiles.

For more than 15 years, Teem Photonics has developed the ioNext platform, an advanced industrial platform for the manufacturing of PIC on glass. These integrated optics components have been delivered to worldwide industrial and academic customers for many years and for many applications including into telecom, bio-medical, energy, defence, scientific research, and other sectors.

Figure 3. Principle of the two-step ion-echange process implemented at Teem Photonics for the manufacturing of PIC on glass.

The principle of the ion-exchange process implemented in the ioNext platform is shown in the above schematic. The method can be split in two steps. The first consists of diffusing silver ions from a molten bath into the glass wafer at high temperature and through the opened windows of a metal mask. In the second step, the waveguide is moved deeper into the glass thanks to the action of an external electric field.

Teem Photonics' platform is based on a custom glass which has been specially optimised for the manufacturing of optical waveguides with low propagation loss and high confinement, low PDL and high PER for telecom applications. The first standard manufacturing process was dedicated to the realisation of waveguides with MFD perfectly fitted to the one of standard telecom fibres to provide very low loss components like splitters, couplers and Taps.

More recently, substantial in-house development work has led to the widening of our waveguides portfolio. As outlined below (Table 2), Teem is now able to offer the manufacturing of optical waveguides with various MFD, refractive index contrast, operating bandwidth and even interaction with the glass surface. The versatility of the ion-exchange technology is such that all these parameters can be tuned along the waveguide path. This is one of the major advantage and differentiation of this ioNext platform over other PIC platforms.

Table 2. Main features of Teem's optical waveguides portfolio

Capabilities and expertise

Along with the development of the manufacturing process, Teem Photonics has been expending its capabilities and expertise in:

optical design to provide new optical functions and components such as duplexers, polarisers, mode converters (implemented in the WAFT component) and interferometers.

pigtailing, assembly and packaging to be able to manage the whole production line of PIC components as well as to hasten the development process for our customers.

Figure 4. PicoMove interferometer (a) principle and (b) product series.

One of the most advanced components is our PicoMove interferometer. It is based on the monolithic integration of a specific Michelson-like architecture (shown above) on a single chip, which provides measurements with a high degree of stability and intrinsic ultra-low noise. The main applications are calibration and metrology of high-precision position sensors and equipment, seismology, vibrometry, and high-precision refractive index measurement "“ to give just a few examples.

Teem proposes an extended line of PicoMove interferometers with various package materials, footprint and optical configurations. The last version even allows for the integration of the sensor in ultra-high vacuum (UHV) environments.

Summary

The ioNext platform on glass offers a flexible, competitive, reliable, scalable and cost-effective solution for the manufacturing of passive photonics integrated circuits and sensors. It also opens new opportunities in the field of silicon photonics chips packaging with the unique features of the WAFT component. Let us know your requirements and we will show you how a little piece of glass can change everything.