The Importance of automated burn-in and test of photonic integrated devices

To keep pace with an increase in the demand for high-performance optical components, producers will need to consider automation of their processes in more detail. Dylan J. Burke of Yelo "“ a firm specialising in automated device measurement "“ looks at what's driving the market and discusses the challenges that device makers face in relation to burn-in and test of devices at high volume. Included in his review are examples of the developments Yelo has been working on to help PIC firms in ramping up production.

The current market scenario

Our digitalised world demands faster network speeds and greater bandwidth. Go to any photonics- or optoelectronics-related industry trade show or conference in the world and it's one of the hot topics on everyone's lips and minds. There is a genuine buzz in the industry "“ 100 Gbps networks are exciting and everyone wants a piece of that market.

We are living in a time where more people are using social media sites and apps to share their videos, pictures, live streams and even virtual reality experiences. There are other developments to consider too, such as big data and cloud computing, the internet of things, and digital healthcare.

Photonic integrated circuits (PICs) are the bedrock of making this happen and to put it into perspective, the use of optical components in the large-scale data centre market is forecast to grow by approximately 700% over the next eight years and the value of this market is estimated to be worth over $400 million by 2024. These are some truly astronomical figures and this demand is going to expand the need for optical components with a speed of 100 Gbps, low power consumption, small die size of 0.25m2 with 20 micron tolerance and 100 micron electrical pad sizes.

The importance of burn-in and test data

To succeed, PICs need to be not just fast, but reliably fast. For light sources, this means applying a burn-in process - in other words, running components under a continuous period of operation to check for defects and ensure that every device shipped is up to standard. The aim of production burn-in is to stress the laser diode crystal structure using higher than normal operating current and operating temperature. Under these conditions a point of so-called infant mortality will be detected. Typical soak temperature ranges from 85°C to 150°C and typical current ranges are 50-150% of the normal operating current.

Having this reliability data is essential to device makers in winning repeat orders and can justify a premium on price. The data also goes hand in hand in appraising new layouts and optimising manufacturing.

The challenges of scaling up

One of the real challenges for companies involved in the industry is how to scale-up their output. What are the options for speeding up the production process, which includes the assembly, packaging and testing of optical devices?

The obvious answer is full automation. As the demand for optical devices increases, the firms that will successfully capture market share will be the ones who can scale-up their production lines using automation to increase the throughput of devices getting into the field. What's more, automation can free-up a firm's engineering resource to be used more efficiently in other areas.

Test solutions

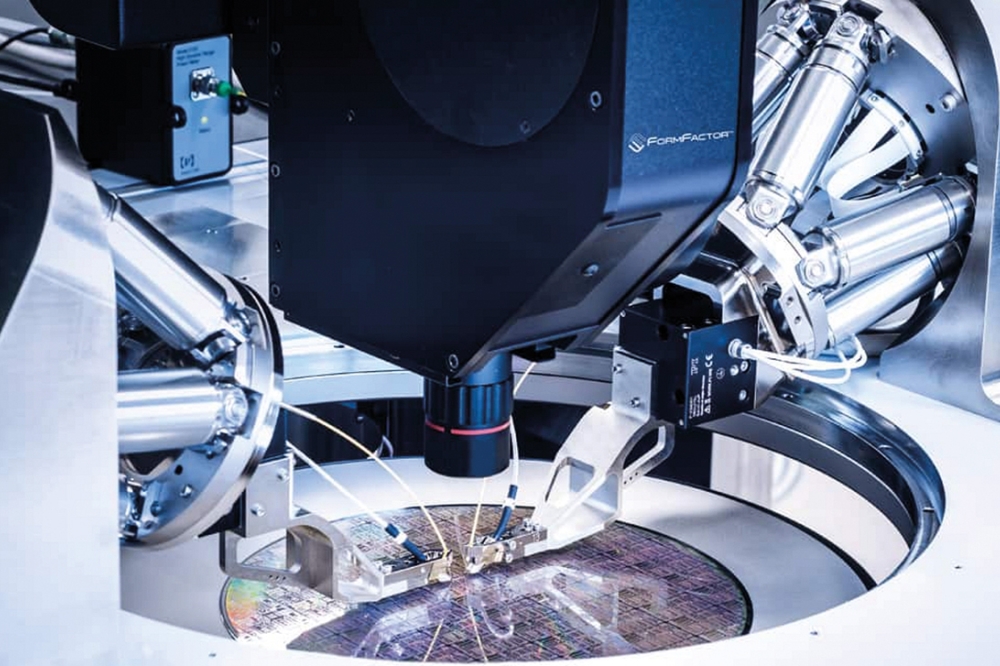

Yelo has been developing a range of test equipment and services to help device makers in scaling-up their processes. Our burn-in systems (see below) along with our support and maintenance services are widely used in the telecommunications and data communications industries and help device makers get the test data they need to produce a qualification report for the requirements outlined in the Telcordia GR-468 document.

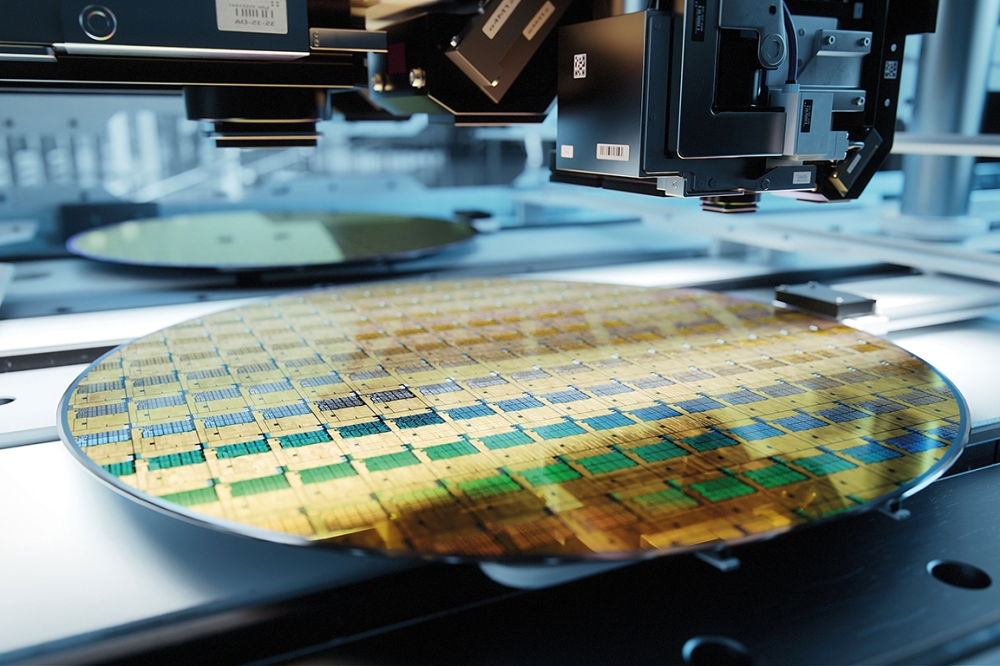

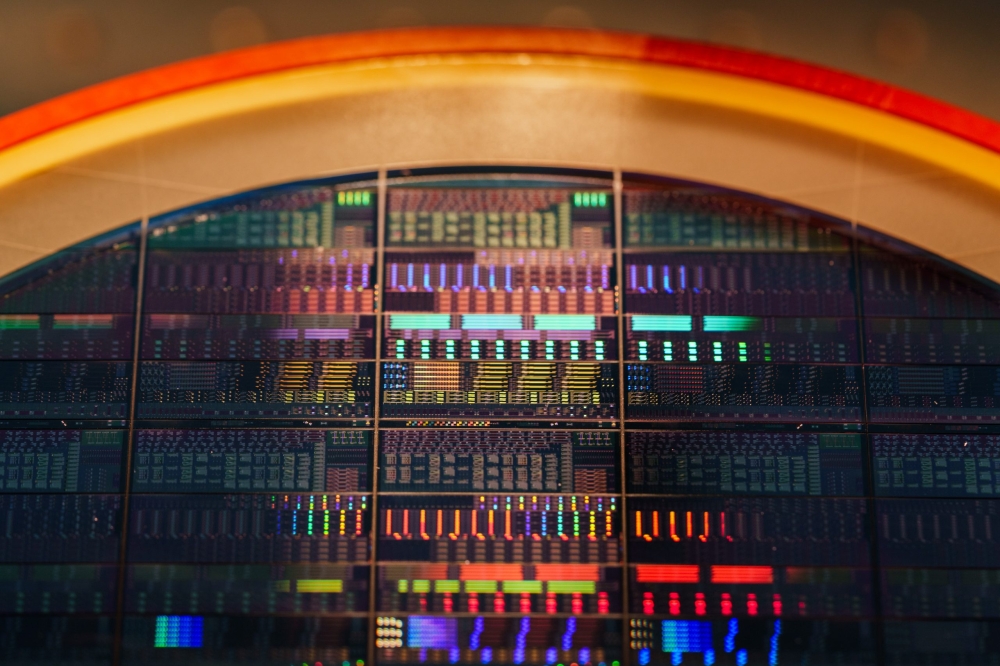

Figure 1. Yelo Y1000L burn-in and life test system.

Yelo wants to ensure that device makers are aware of the importance of having reliability test data. To give an example - we recently worked with a leading US based scientific instrumentation organisation that didn't have any data, but needed their devices to have a 10 year lifetime. It actually turned out that their devices had a 50% failure rate after just 6 months and were late in getting their product to market. To help them, we were able to propose a detailed life test strategy which included;

Current and Temperature Conditions

Multiple Current Zones

Multiple Temperature Zones

Analysis and Provisions of lifetime for each optical device

We also had a discussion with an academic institution on best practice for experiments and test procedures. Yelo are currently testing their devices in-house and are sending the client reliable test data every two weeks and they now have a competitive product to take to market with a reduction in warranty costs and field visits.

New additions

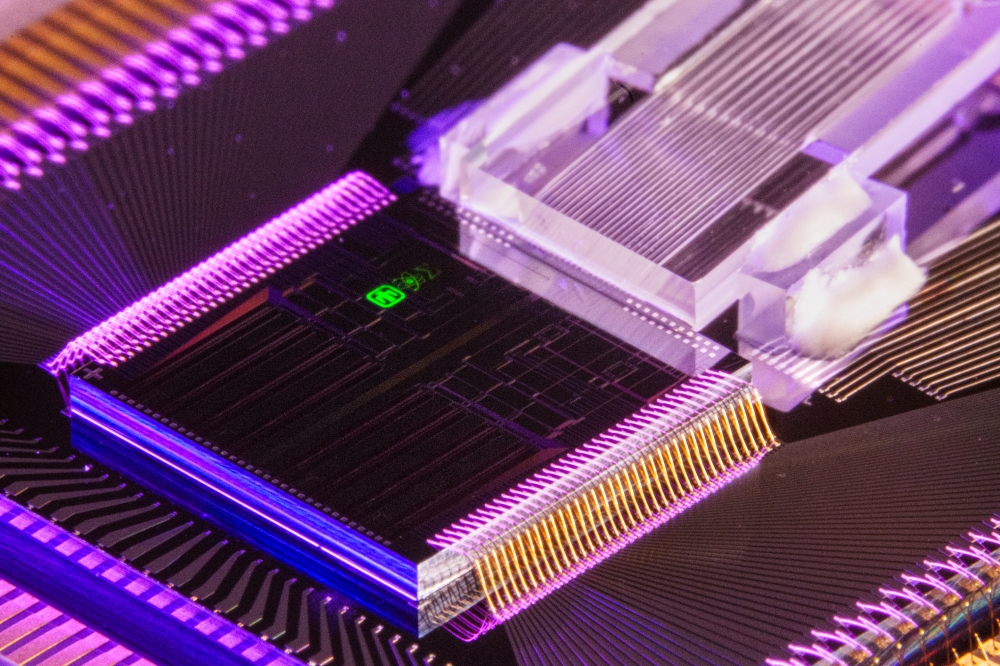

Our most recent development is the LIV (light "“ current "“ voltage) test instrument (figure 2) and works as an integral part of the testing process. Our typical process is to perform a pre burn-in LIV measurement on devices, burn-in devices at the conditions required by the client and then perform another post LIV measurement to monitor any change in threshold.

Figure 2: Yelo LIV test instrument with test fixture

Other hurdles to overcome

Challenges remain for burn-in and test "“ for example, as devices move to smaller sizes, the handling of components will need to adapt accordingly. At Yelo, we are actively researching and developing solutions to these problems.