ficonTEC launches multi-site die-level test system for double-sided compact optical engines

The company says this latest addition to its systems targeting co-packaged optics manufacturing offers a scalable configuration that significantly reduces test cost while maintaining high repeatability

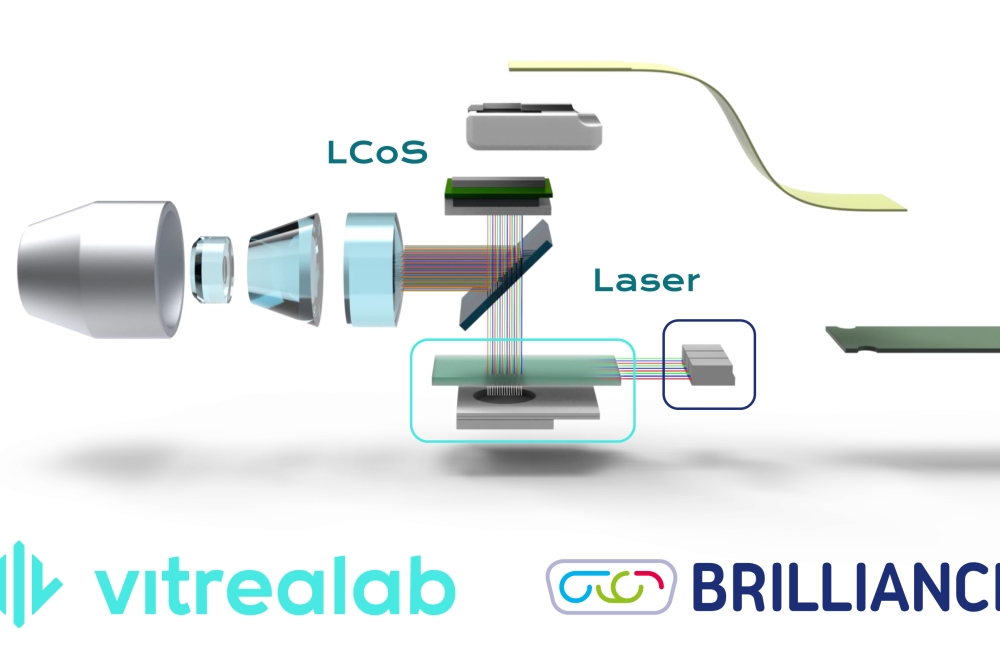

ficonTEC has announced the launch of the DLT-D1, a next-generation high-throughput, multi-site parallel test handler designed specifically for double-sided compact optical engines. The company says this new product extends its co-packaged optics (CPO) test ecosystem, addressing the growing demand for 2.5D and 3D CPO architectures in high-performance computing (HPC) and data switching applications.

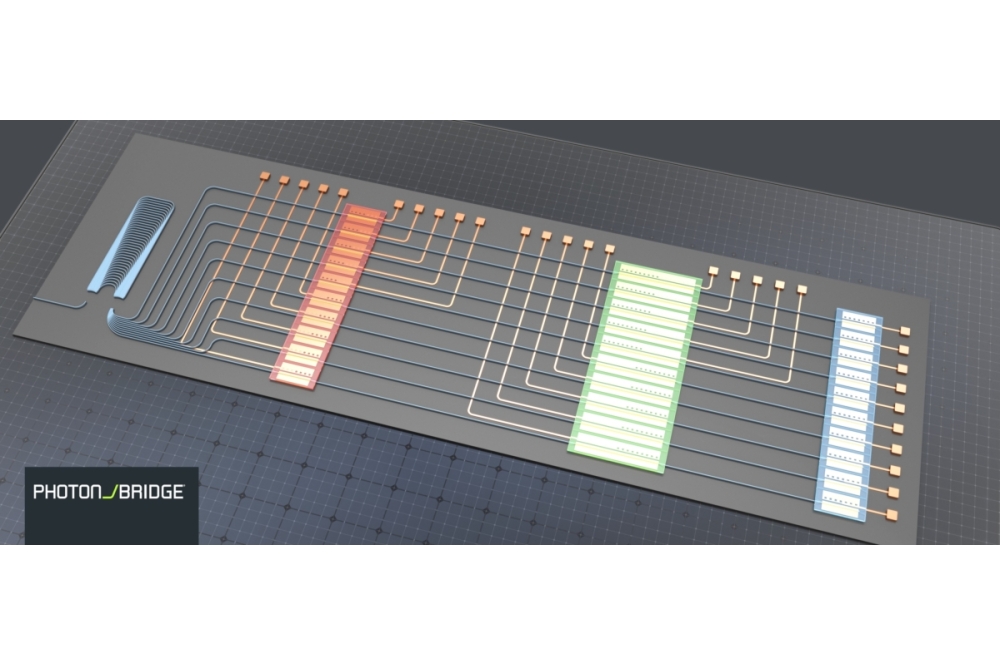

According to ficonTEC, the system supports everything from DC parametric measurements to full data-rate RF testing, combining active optical alignment from the bottom-side of the device under test (DUT) with high-frequency electrical probing from the top-side. For DUTs with receptacles attached, the DLT-D1 can alternatively provide automated fibre coupling, the company adds, while a fully automated JEDEC magazine tray loader streamlines device handling, making the platform ideally suited for OSATs and other high-volume production environments.

Engineered for maximum productivity, the DLT-D1 can operate with up to three parallel test heads connected to either automated test equipment (ATE) or dedicated instrumentation, ficonTEC notes. This scalable configuration is aimed at significantly reducing test cost while maintaining high repeatability, helping customers accelerate time-to-market.

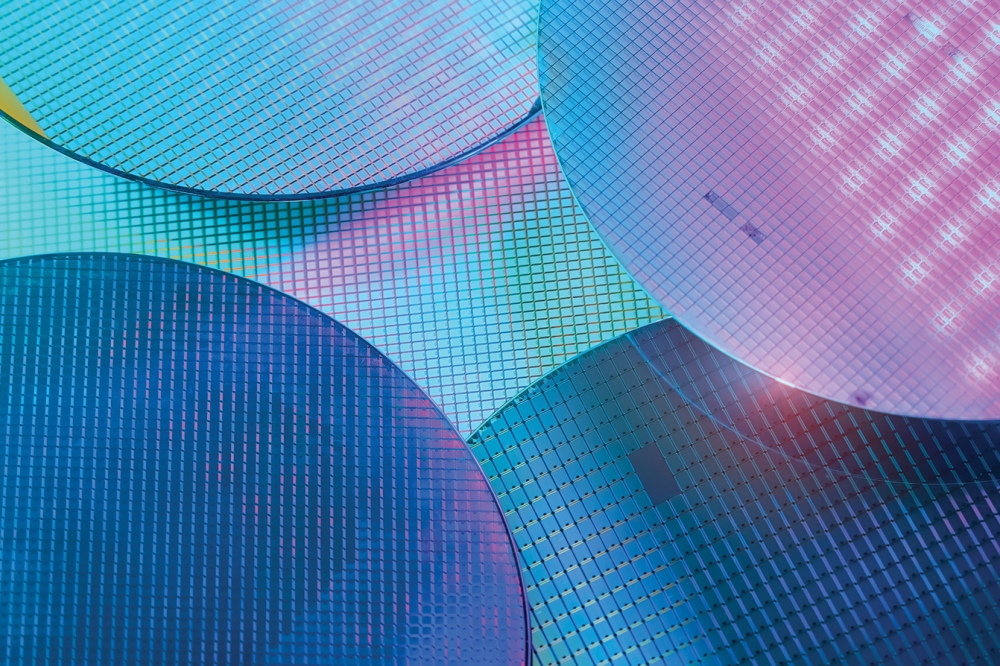

With the addition of the DLT-D1 to its previously announced double-sided wafer-level tester (WLT-D2) and single-sided wafer-level tester (WLT-S2), ficonTEC says it now delivers the industry’s most comprehensive test portfolio – from wafer to die-level – all built on a unified software interface and common test data framework.