OKI develops tiling process to integrate InP on silicon

The company has demonstrated its crystal film bonding technique to achieve the heterogeneous integration of small-diameter InP optical semiconductor wafers onto 300 mm silicon with high accuracy

OKI has announced it has successfully developed Tiling crystal film bonding technology using its proprietary CFB technology. The company says this technology enables the heterogeneous integration of small-diameter optical semiconductor wafers onto 300 mm silicon wafers, which was previously not possible due to wafer size restrictions, and will contribute to the advancement of rapidly growing photonics-electronics convergence technology. OKI aims to achieve early commercialisation through collaboration with partner companies and universities.

Rapid advances in AI in recent years has fuelled growing demand for datacentres, creating an urgent need to suppress increases in power consumption while expanding data processing capabilities. One solution that has drawn attention is the combination of electronic and photonic circuits to achieve high-density, high-speed transmission, and low power consumption. In particular, the heterogeneous integration of optical semiconductors onto silicon wafers is expected to improve performance still further by enabling the integration of silicon photonics with optical semiconductors.

Nevertheless, heterogeneous integration presents various technical challenges. For example, while silicon photonics uses large-diameter 200 mm or 300 mm silicon wafers, optical semiconductor wafers such as indium phosphide (InP) wafers are typically smaller 50 mm to 100 mm compound semiconductor wafers due to the difficulty of achieving epitaxial growth. Additionally, silicon optical waveguides require nanoscale roughness control, which in turn requires heterogeneous integration processes that avoid causing damage.

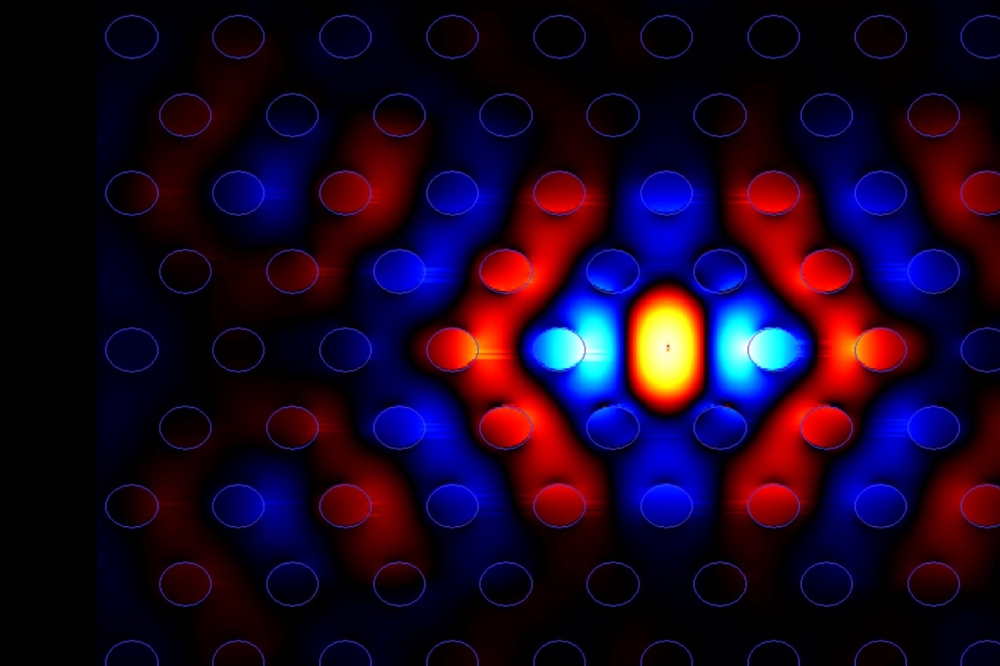

OKI says the Tiling CFB technology it has developed overcomes this disparity in wafer sizes and allows heterogeneous integration without causing damage. The company describes how the technology allows for 52 repeated tiling operations over the entire surface of a 300 mm silicon wafer using a single 2-inch InP wafer, enabling efficient use of InP-based materials. The InP wafer can be reused as is after transfer to allow material recycling and reuse, helping reduce the environmental burden. According to OKI, the technique demonstrates placement accuracy of approximately ±1 μm, with an angular accuracy of ±0.005 degrees, which, when combined with OKI’s proprietary 3D intersecting waveguide silicon photonics technology, realises high-efficiency optical coupling between optical semiconductors and silicon waveguides.

In a demonstration, a sacrificial layer and InP-based Crystal Films functioning as optical semiconductors were epitaxially grown on a 2-inch InP wafer, then separated into individual elements. A protective structure to prevent chemical attack when etching the sacrificial layer and a support structure for batch transfer were formed on each element. This enabled the InP-based Crystal Films to be successfully batch-transferred to an intermediate transfer substrate without erosion. Batch transfer to an intermediate transfer substrate is carried out to protect the silicon wafer from damage during the subsequent removal process, as removing the protective structure and support structure on the intermediate transfer substrate prevents damage to the silicon wafer during the removal process. According to OKI, the unique design of the intermediate transfer substrate ensures that the InP-based Crystal Films do not peel off, maintain adhesion during the process of removing the protective structure and support structure, and are easily transferred during the transfer process.

Furthermore, by repeatedly transferring Crystal Films from the intermediate transfer substrate using a CFB stamp, the company says it has established Tiling CFB technology that enables tiling over the entire surface of a 300 mm silicon wafer. The CFB stamp has a structure capable of selectively transferring only the Crystal Films required, and repeated transfer enables efficient tiling. The capacity to repeatedly transfer lower-density arrays of Crystal Films required for the device from a high-density array of Crystal Films arranged on the intermediate transfer substrate allows effective use of materials without waste. Measuring 30 mm × 30 mm, the CFB stamp used in this demonstration completed 52 transfers onto the entire surface of a 300 mm silicon wafer in approximately 10 minutes, adds OKI, sufficient for commercial production.

This demonstration showed the feasibility of Tiling CFB technology in the transfer from 2-inch wafers to 300 mm silicon wafers, and the technology can also be adapted as necessary to allow use with 3- or 4-inch InP wafers and 200 mm silicon wafers, says OKI. Since it can also be applied with existing optical semiconductor products, it will help improve performance by permitting transfer to high heat-dissipation substrates and productivity by allowing use of larger wafer sizes, adds the company.

Tiling CFB technology also aims to contribute to the advancement of photonics-electronics convergence technology and a reduced environmental burden. OKI plans to strengthen collaboration with device manufacturers to achieve early commercialisation of the technology.